Knoll Midifix

The KNOLL MidiFix is an extremely compact machine for processing grass & straw materials into round midi bales. When developing the MidiFix fixed-chamber bale wrapping combi, our goal was to develop a professional machine for maximum usability and impact.

THE BALER/WRAPPER COMBINATION FOR DEMANDING USERS!

The heart of the MidiFix consists of a bale chamber equipped with 14 symmetrical chamber rollers which guarantee an exceptionally high bale density and bale rotation for all types of crops and under all conditions.

The bale-transfer system in combination with a fast wrapper equipped with a double wrapping arm gives a KNOLL MidiFix an unmatchable capacity. A user experiences enormous working pleasure during every job where the MidiFix is used!

BASIC INFORMATION

- Bale size 85 cm (width) x 90 cm (Ø)

- Bale volume: 0.55 m3.

- Bale weight 75-150 kg.

- Bale chamber system with fixed bale chamber and press rolls

- 14 heavy-duty bearing balechamber rollers with rib profile

- Pick-up working width: 1.70 mtr

- Steered pickup with 4 rows of teeth

- Powerful rotor feed system combined with cutting device

- Cutting device equipped with 7 blades (can be switched on/off during work)

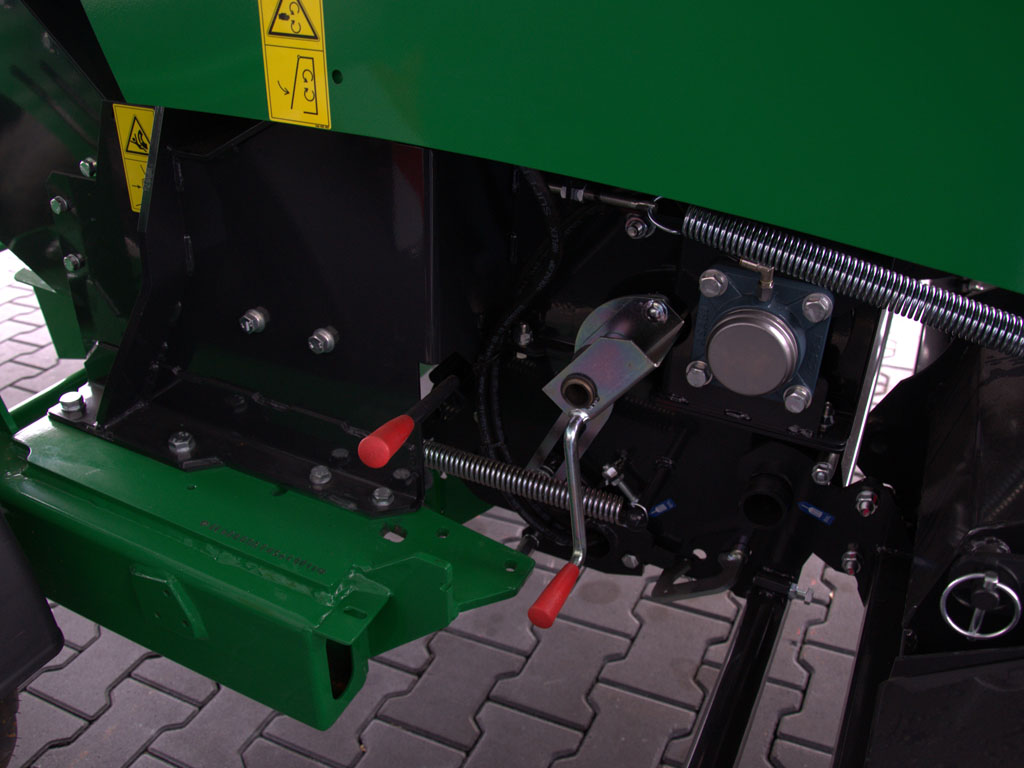

- Mechanical dropfloor system for the elimination of input blockages

- Double arm wrapper with 500 mm film stretchers

- Automatic film break detection system

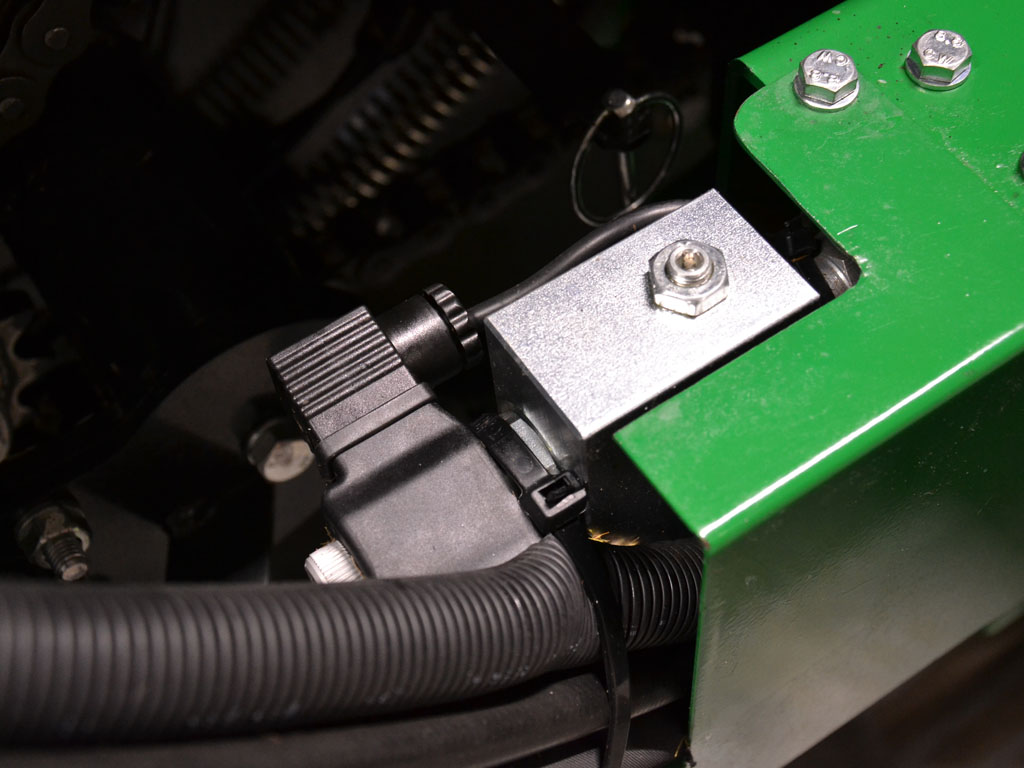

- Modern computer (7-inch) for fully automatic operation

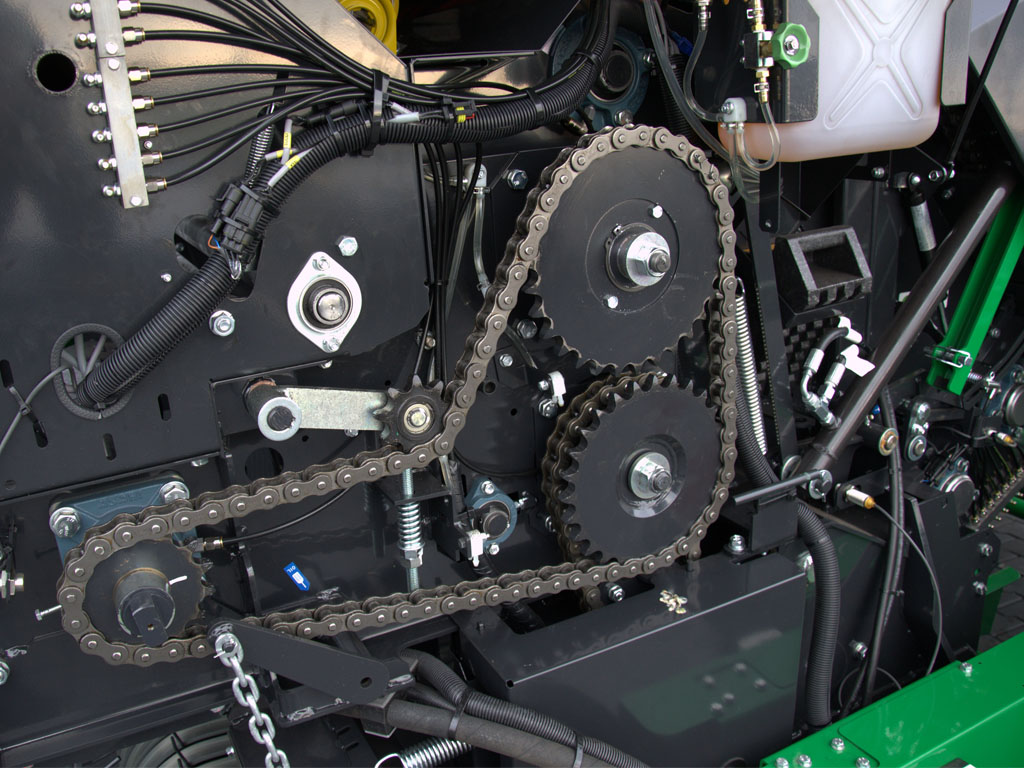

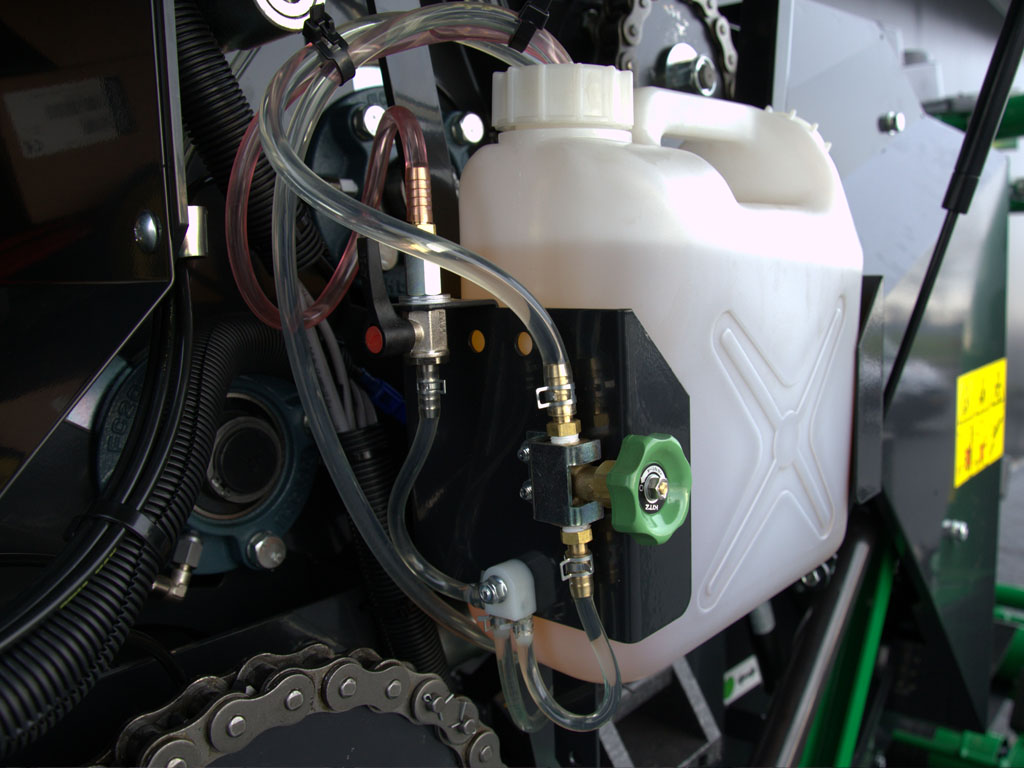

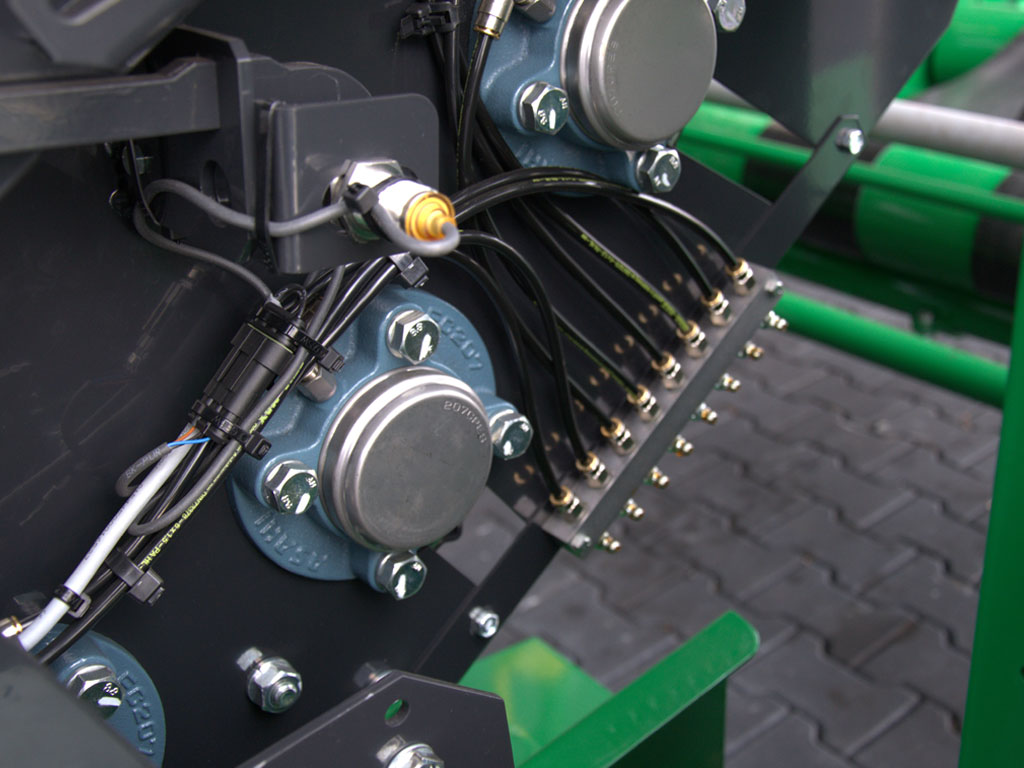

- Automatic oil lubrication system for drive chains

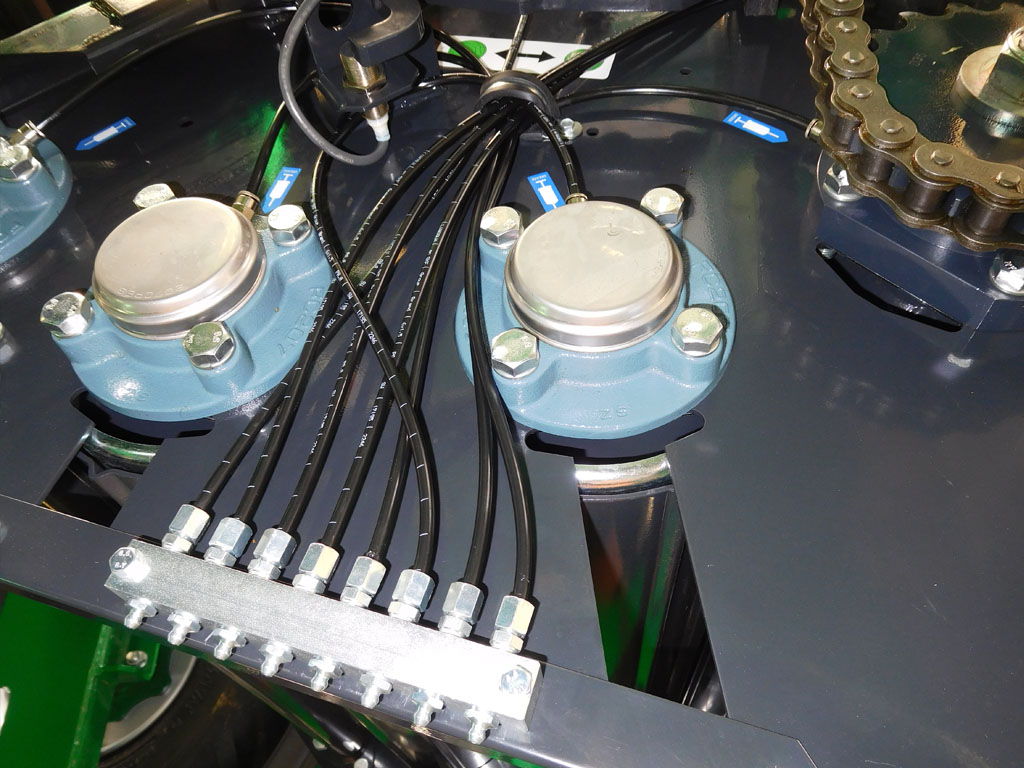

- Central-point grease lubrication system for rolling bearings

- Camera system (display integrated into computer)

- LED worklight (operation integrated into computer)

- External keypads on the machine for quick control of functions

- Single axle chassis with Flotation tires 500/50 R17

- Extra storage for 10 rolls of wrapping film

- Additional storage for 1 roll of net

THE ONE-MAN COMBINATION, EVERYTHING UNDER CONTROL!

KNOLL MidiBalers make expectations come true! Our machines combine the operations of baling and wrapping in one machine.

This ensures an efficient and effective process that guarantees high reliability and capacity (number of bales/hour).

This working method of KNOLL MidiBalers ensures that bales of the best quality can be produced due to direct air exclusion which ensures the best feed quality. In addition, this combined mode of operation ensures economic use of the machine by using only one tractor and operator.

Thoughtful technology and an efficient process ensure the highest possible efficiency. A fully automatic process ensures easy operation.

Know-how from “our own house” which makes working with KNOLL MidiBalers a pleasure!

COMPACT DESIGN

PICK-UP FOR MAXIMUM CROP INTAKE

ROTOR FEED WITH CUTTING SYSTEM

OPTIMAL BALING DENSITY

WRAPPING OF THE BALE

FAST & EFFECTIVE BALE TRANSFER SYSTEM

A feature of KNOLL MidiBalers is the rapid movement of the bale from bale chamber to wrapping position. This reduces the time of standing still. The bale transfer system ensures a direct transfer of the bale from the bale chamber to the wrapping position; fast, clean and efficient. The wrapping table in this machine moves by means of a cylinder which is attached to a command steering arm from loading to wrapping and unloading position. At the start of the baling process the wrapping table already moves to the loading position. Upon opening the bale chamber door, the bale then enters the wrapping table directly. From here, the bale moves to the wrapping position, where it is already wrapped a few seconds later. While the wrapping table moves to the wrapping position, the tailgate already closes. Baling can be started immediately. Two bale guiding rollers ensure stable guiding. This guarantees reliable movement of the bale in all conditions and also on sloping terrain.

A MIDI BALE FITS THROUGH ANY DOOR!

A midi bale has characteristics that make this type of bale particularly interesting for the end user. This type of bale is constantly increasing in popularity and has acquired its 'own' place in the market.

1) Low feed rate. Also useful for the small or hobby farmer

2) Small bale size. Less chance of heating and mold

3) Fits through any door. Light weight and easy to move

4) Packaged airtight and dust-free. Wrapped in wrapping film, long shelf life

5) Logistics. Midi bales are easy to move and transport

A midi bale has an average weight of 75-150 kg, depending on the product being processed.

In proportion, one midi bale equals:

3 - 4 small conventional haybales

- 1/3 large round bale

Media

Watch videos and photos of the KNOLL MidiFix below.

Features

View all features of the KNOLL MidiFix.

Robust drive system

Modern operating system

Progressive press pressure control

Dropfloor against crop blockages

Automatic oil lubrication system

Central point lubrication system

External control wrapper

Load sensing hydraulics

Bale side unloading system

Camera & LED work light

Operation with one film roll

TECHNICAL DATA

DIMENSIONS AND WEIGHT | |

|---|---|

Transport length | 4,50 mtr |

Transport width | 2,65 mtr |

Transport height | 2,25 mtr |

Wheels | 500/50 R17 |

Weight | 2.620 kg |

Brake System | N/A, unbraked (brake system optional) |

POWER REQUIREMENTS | |

|---|---|

Required tractor power | Min. 52 kW/ 70hp |

BALE SIZE & CONTENTS | |

|---|---|

Bale size (width x diameter) | 85 cm x Ø 90 cm |

Bale volume | 0.55 m3 |

Pick-up | |

|---|---|

Working width | 1,70 mtr |

Number of tooth rows | 4 |

Feed rotor with cutting blades | Yes, incl. 7 cutting blades (mechanically operated) |

Dropfloor | Yes (mechanically operated) |

MOUNTING & DRIVE SYSTEM | |

|---|---|

Attachment to tractor | a) Drawbar for lifting device, CAT. II |

b) Drawbar for lower / upper coupling | |

PTO | 1-3/8″ (6 splines) – 540 RPM |

HYDRAULIC SYSTEM | |

|---|---|

Hydraulic System | Open center hydraulics from tractor |

Hydraulic connections | 1 pressure connection 1/2″ 1 pressure return connection 3/4″ Minimum 25 ltr/min flow rate

|

Load-sensing hydraulic system | Optional |

ELECTRIC SYSTEM | |

|---|---|

Electrical connections | 12 volt DC & road lighting |

Operator system | CrossControl 7″ TFT touchscreen + key operation (dust and water resistant)

|

WINDING & WRAPPING SYSTEM | |

|---|---|

Wrapping System | Double wrapping arm with 500 mm film stretch units |

Binding System | Netbinding |

Film break detection system | Yes, automatic for both binding & wrapping system |

Extra storage of wrapping film (rolls) | 10 |

Additional storage net (rolls) | 1 |

Downloads

Download our digital brochure of the KNOLL MidiFix here.

Looking for working drawings, manuals or parts lists?

Please feel free to contact us.

ADDITIONAL OPTIONS

KNOLL attaches great importance to meeting the expectations of customers worldwide. In order to meet all requirements and wishes, KNOLL MidiBalers can be equipped with additional options so that the machines perfectly match the working environment in which the performance is to be delivered.

APPLICATIONS

Processing various crops and materials into high-density round bales is what KNOLL MidiBalers excel at!

Our MidiBalers can be used to process grass, hay, straw and alfalfa, among others, into high-density round midi bales.

Grass

Hay / haylage

Straw

Examples of other materials that can be processed with a KNOLL MidiFix.

Alfalfa | Lucerne