Knoll Midifix II

The KNOLL MidiFix II is our latest development in the field of MidiBalers. The MidiFix II combines the operations of pressing and wrapping in one machine. In developing this new model, we asked ourselves the question, “what does a professional user expect from a KNOLL MidiBaler?”

By developing a new machine from this point of view, we have succeeded in offering a professional machine that scores on the basis of many highlights.

POWERFUL, DECISIVE AND FAST. FOR HIGHLY PROFESSIONAL USE!

A MidiFix II consists, just like the regular MidiFix, of a bale chamber equipped with 14 symmetrical chamber rollers which guarantee an exceptionally high bale density and bale rotation. The MidiFix II is equipped with a newly developed wrapper which ensures a reliable and fast bale transfer. In combination with a fast wrapper equipped with a double wrapping arm, this ensures an unmatched capacity.

The MidiFix II is a machine for professional users and is therefore perfectly suitable for users working in contract work. It does not matter what kind of product is being processed, silage, hay or straw bales. The machine is very easy to operate and is fully automatic. Also in combination with the optional film binding this machine distinguishes itself in the market segment!

BASIC INFORMATION

- Bale size 85 cm (width) x 90 cm (Ø)

- Bale volume: 0.55 m3.

- Bale weight 75-150 kg.

- Bele chamber system with fixed press chamber and press rolls

- 14 heavy-duty bearing bale chamber rollers with rib profile

- Pick-up working width: 1.70 mtr

- Steered pickup with 4 rows of teeth

- Powerful rotor feed system combined with cutting device

- Cutting device equipped with 7 blades (hydraulically switched on/off)

- Hydraulic dropfloor system for the elimination of input blockages

- Double arm wrapper with 500 mm film stretchers

- Renewed bale transfer system from bale chamber to wrapper

- Automatic control of 50% overlap wrapping film (speed independent)

- Automatic film break detection system

- Modern computer (7-inch) for fully automatic operation

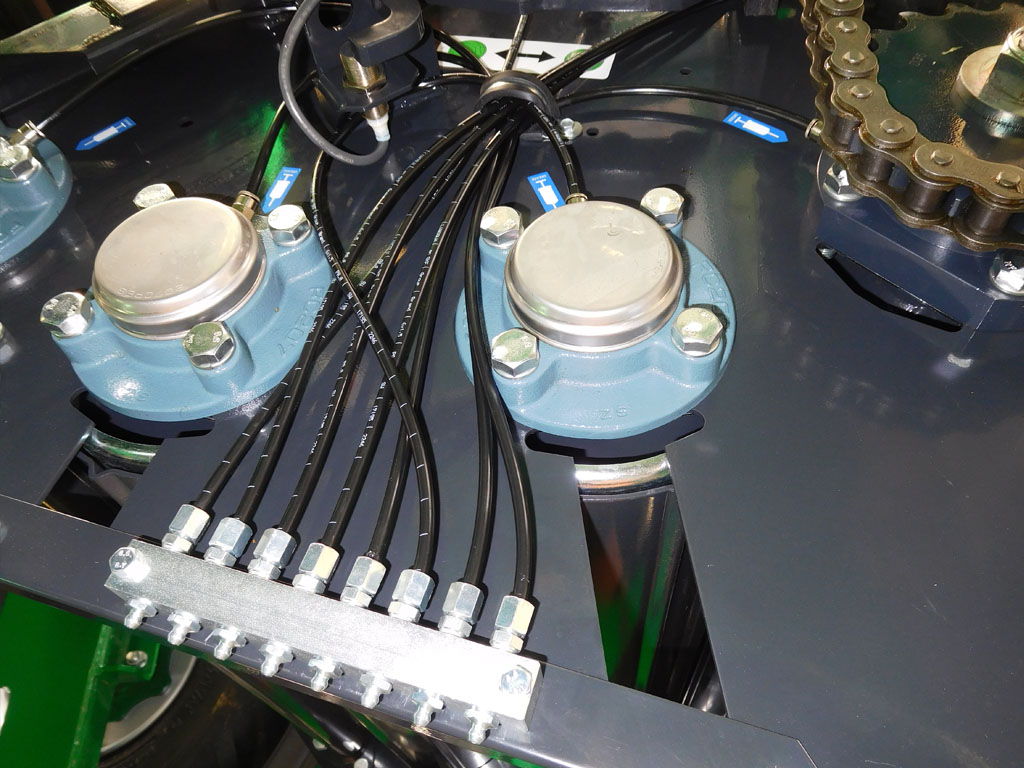

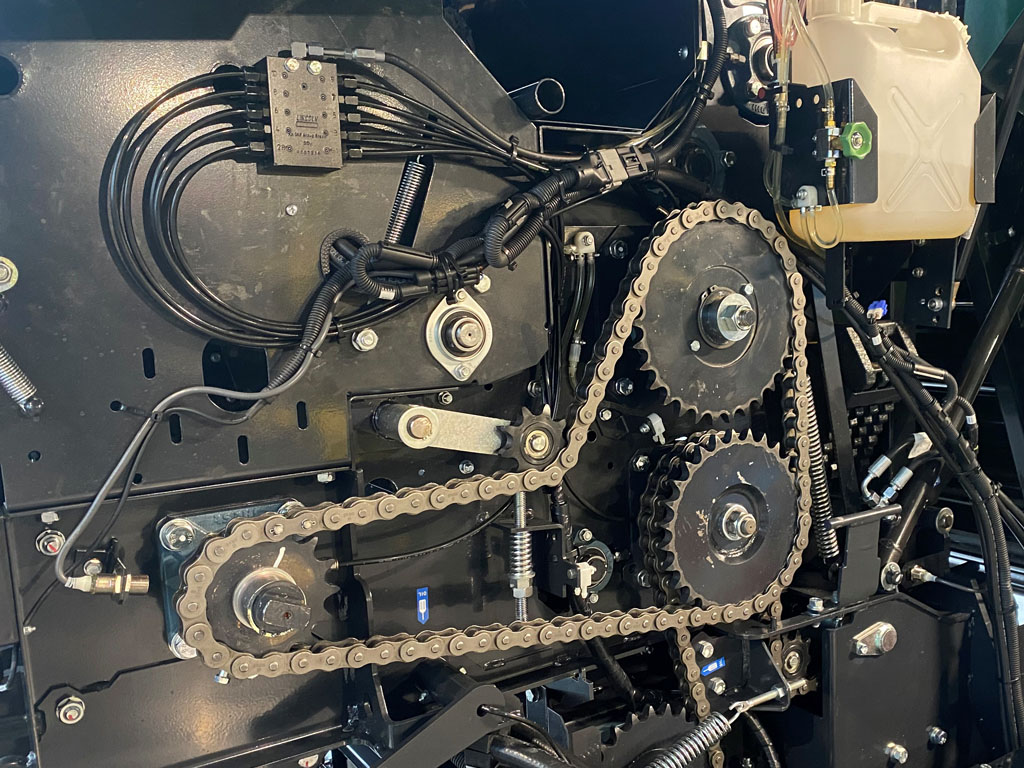

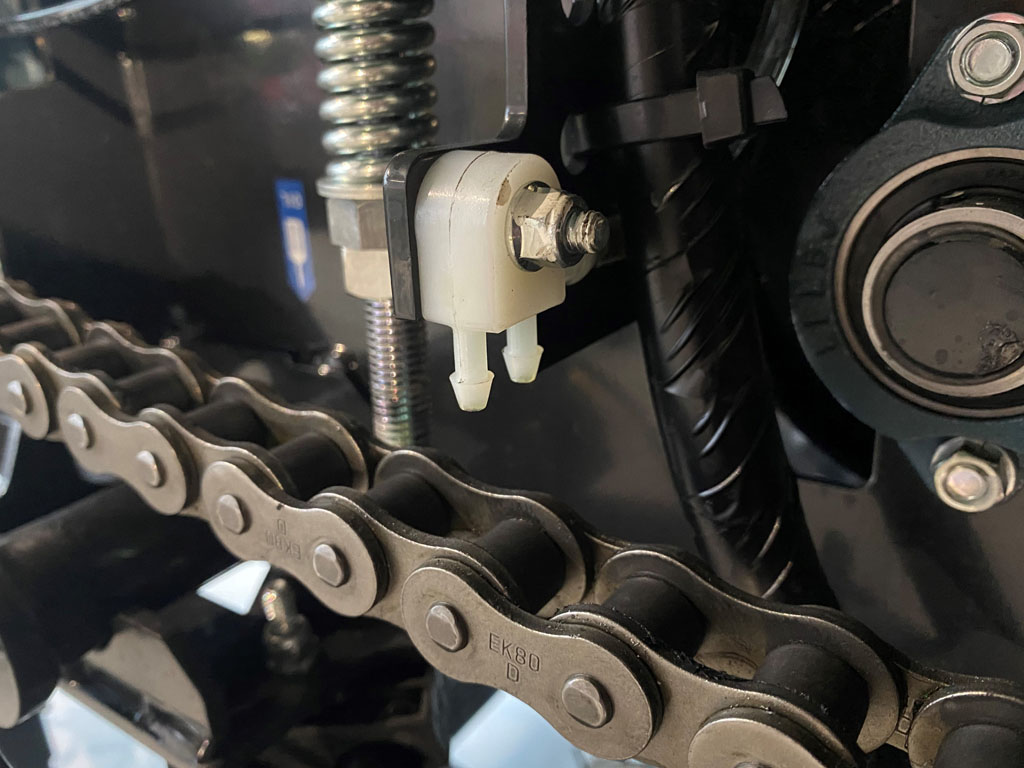

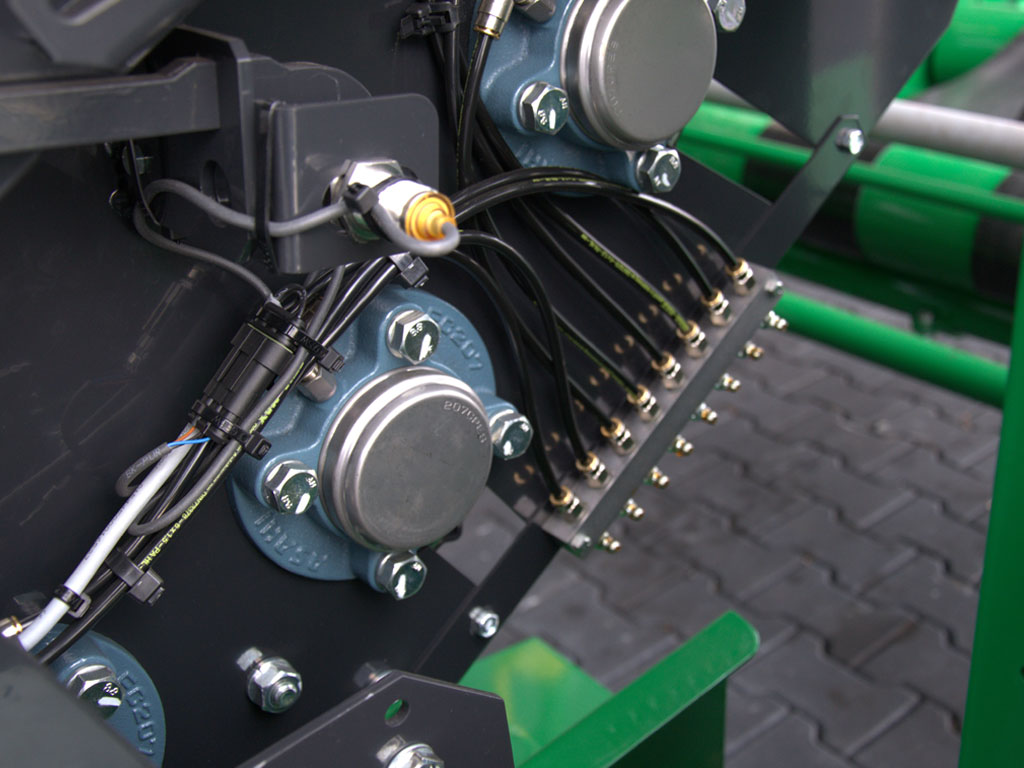

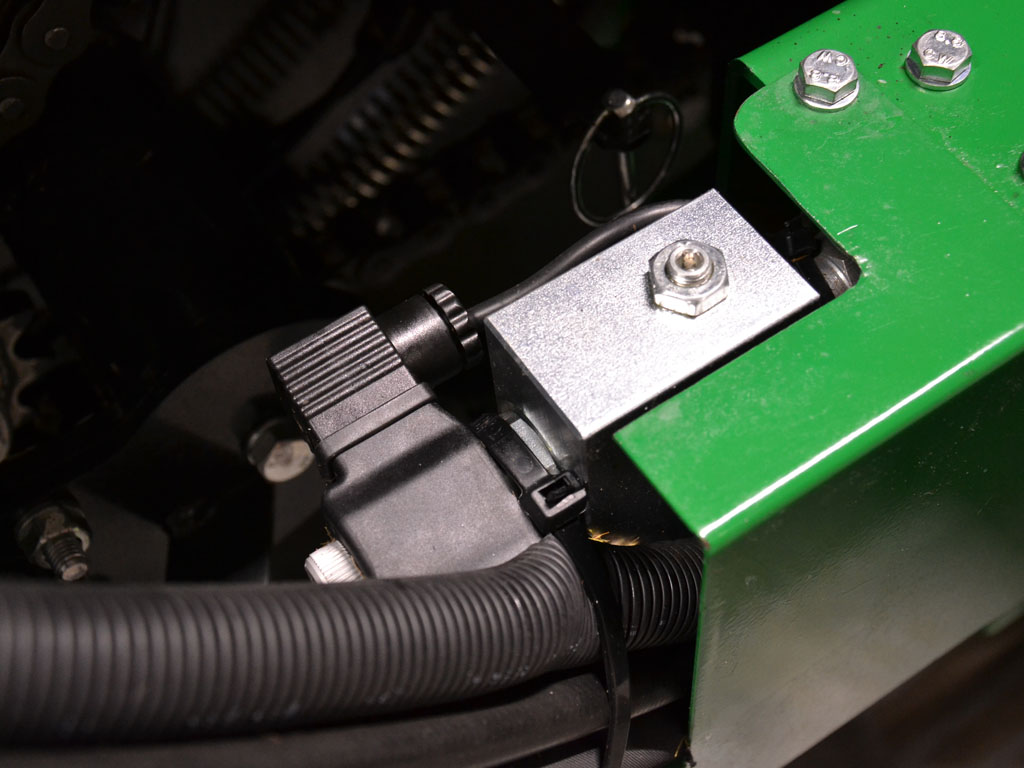

- Automatic oil lubrication system for drive chains

- Proportional hydraulic system for precise control of functions

- Central-point grease lubrication system for rolling bearings

- Camera system (display integrated into computer)

- LED worklight (operation integrated into computer)

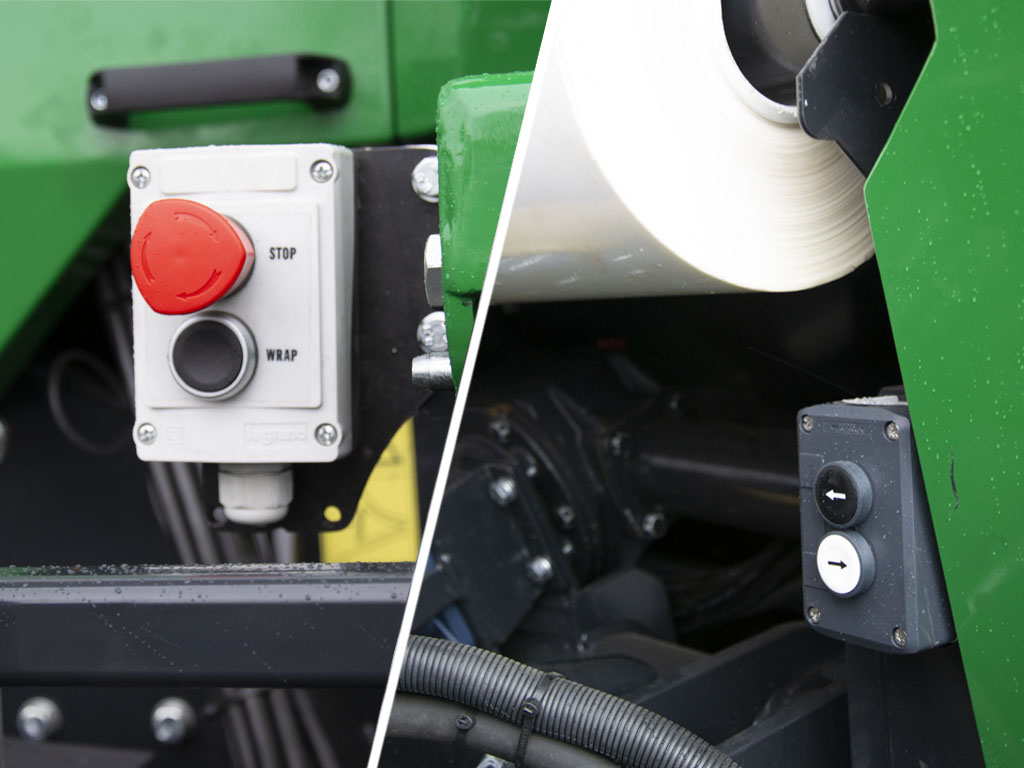

- External keypads on the machine for quick control of functions

- Single axle chassis with Flotation tires 500/50 R17

- Extra storage for 10 rolls of wrapping film

- Additional storage for 1 roll of net

A COMBINATION FOR PROFESSIONALS, SIMPLY THE BEST!

KNOLL MidiBalers make expectations come true! Our machines combine the operations of pressing and winding in one machine.

This ensures an efficient and effective process that guarantees high reliability and capacity (number of bales/hour).

This working method of KNOLL MidiBalers ensures that bales of the best quality can be produced due to direct air exclusion which ensures the best feed quality. In addition, this combined mode of operation ensures economic use of the machine by using only one tractor and operator.

Thoughtful technology and an efficient process ensure the highest possible efficiency. A fully automatic process ensures easy operation.

Know-how from “our own house” which makes working with KNOLL MidiBalers a pleasure!

COMPACT DESIGN

The robust but compact construction of a KNOLL MidiFix II allows the machine to be used in all conditions. The stable frame guarantees a long service life for the machine. The single-axle construction with large wheels makes the machine particularly maneuverable.

The low center of gravity ensures perfect crop pickup by the pickup and excellent maneuverability.

Due to the even weight distribution and the single-axle construction, the MidiFix II has excellent driving characteristics, even when distances need to be covered.

PICK-UP FOR MAXIMUM CROP INTAKE

Making a good midi bale starts with proper intake of the base product. Exact and short cut forage is the basic requirement for producing quality silage. The pick-up of the KNOLL MidiFix II with 4 rows of tines ensures maximum intake capacity through its excellent ground adaptation. The steered pick-up with a working width of 1.70 m is equipped with large augers on both sides which ensure an optimum material flow to the rotor, even with wide swaths. In front of the rotor is a mechanically driven crop roller. This ensures excellent compaction of the material and increases the feed capacity.

ROTOR FEEDING & CUTTING SYSTEM

A quality product can only be delivered when the crop is cut short and effectively.

A 3-star rotor with high intake capacity is built into the feed system. With a diameter of 400mm and welded rows of teeth, the rotor transports large, dry swaths as well as short swaths effectively into the bale chamber.

The rotor feed system of a MidiFix II is designed for optimal feed intake in all conditions.

The hydraulically operated cutting device is located at the bottom of the rotor. The cutting device is equipped with 7 cutting knives. Due to the very small distance between the rotor teeth and the knives, the feed is cut precisely.

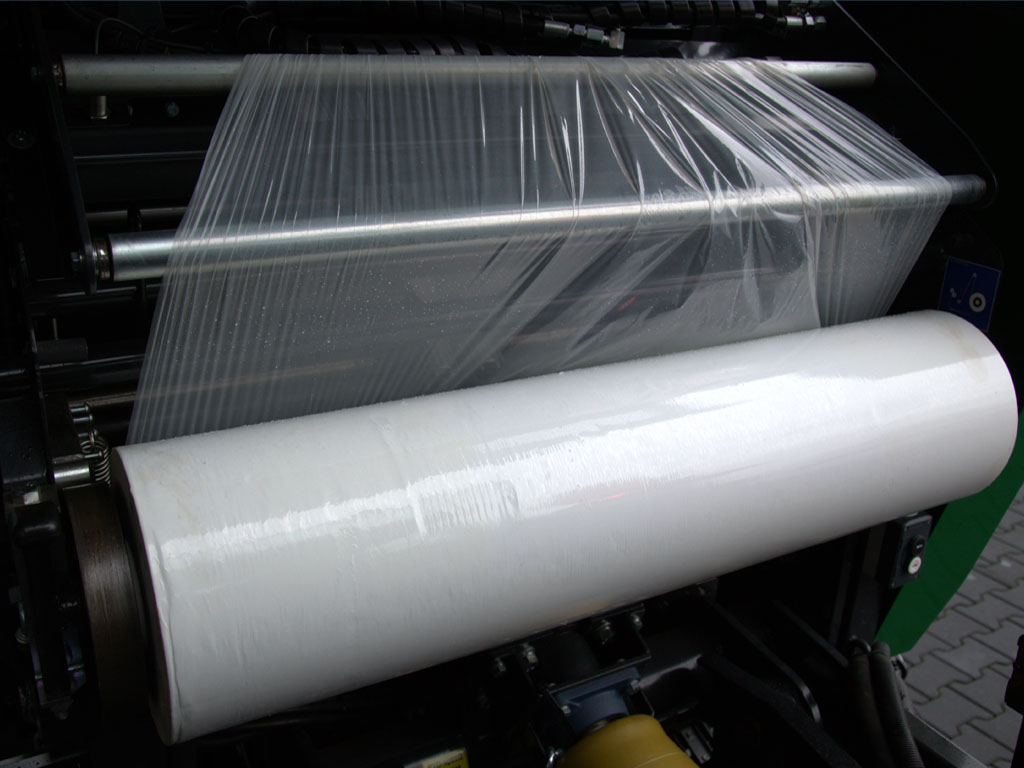

FILM & NET BINDING SYSTEM

A KNOLL MidiFix II is equipped with a net binding system as standard. Optionally, the machine can be equipped with a film binding system. With film binding, net rolls can of course still be installed.

The use of mantelfilm offers substantial advantages for improving silage quality.

With mantel film, the bales become more compact and are better protected by the film layers. Film and film provides an additional oxygen barrier.

The bales can be opened and recycled more easily because the mantelfilm and wrapping film can be removed together as one waste product.

OPTIMAL PRESS DENSITY

At the center of the machine is the pressing chamber with a size of 85 cm. x 90 cm. The pressing chamber is an important part of the machine. It consists of 14 heavy-duty roller presses which rotate on roller bearings. These rollers have a special profile in order to create the highest possible press density. Directly behind the rotor is the special 'front roller', which ensures an optimal rotation of the bale - regardless of the type of crop being pressed.

The tailgate is equipped with mechanical hooks which keep the press chamber closed during the feeding process and simultaneously ensure the highest possible press density.

WRAPPING OF THE BALE

The KNOLL MidiFix II is equipped with a wrapping table which drives under the bale chamber at the start of the baling process. As soon as the bale is tied, it is transported to the wrapping position without ground contact. Direct transfer of the bale; fast, clean and without additional loading arm.

Moving the bale is easy, reliable and safe - even on sloping terrain. The bale transfer takes a few seconds, so that downtime is minimal.

The MidiFix II is equipped with a double wrapping arm with two 500 mm film stretch units. The automatic film control immediately stops wrapping when there is an empty roll of wrapping film or when the film tears. One can also continue wrapping with one film roll after this and automatically double the number of wraps.

FILM BINDING SYSTEM FOR BETTER PRESERVATION

A KNOLL MidiFix II can optionally be equipped with a film binding system. When this is present on the machine, it is also still possible to use net. Changing film or net is just changing a setting in the control system.

The use of mantel film offers proven benefits for improving silage quality:

1) Press density / bale density. Bales become more compact and are better protected by the film layers. Also, the presence of mantel film provides an additional oxygen barrier.

2) One type of residual waste. Mantel and wrapping film can be processed as one residual product after the bale is opened. This simplifies the opening and recycling of bales.

For proper application, a net roll of 105 cm and a mantel film roll of 100 cm should be used. The mechanically adjustable braking force system ensures tightly wrapped bales with net or mantel film.

A MIDI BALE FITS THROUGH ANY DOOR!

A midi bale has characteristics that make this type of bale particularly interesting for the end user. This type of bale is constantly increasing in popularity and has acquired its 'own' place in the market.

1) Low feed rate. Also useful for the small or hobby farmer

2) Small bale size. Less chance of heating and mold

3) Fits through any door. Light weight and easy to move

4) Packaged airtight and dust-free. Wrapped in wrapping film, long shelf life

5) Logistics. Midi bales are easy to move and transport

A midi bale typically has a weight of 75 -150 kg, depending on the product being processed.

In proportion, one midi bale equals:

3 to 4 small square hay bales

- 1/3 large round bale

Media

Watch videos and photos of the KNOLL MidiFix II below.

Features

View all features of the MidiFix II

Machine with capacity!

Fast bale movement

Powerful drive system

Modern operating system

Progressive press pressure control

Dropfloor against crop blockages

Automatic oil lubrication system

Central point lubrication system

Control element with push buttons

Load sensing hydraulics

Bale side unloading system

Camera & LED work light

Operation with one film roll

Technical data

Dimensions and weight | |

|---|---|

Transport length | 5,30 mtr |

Transport width | 2,65 mtr |

Transport height

| 2,15 mtr |

Wheels

| 500/50 R17 |

Weight

| 3.025 kg |

Brake System

| N/A, unbraked (brake system optional) |

POWER REQUIREMENTS | |

|---|---|

Required tractor power | Min. 52 kW/ 70hp |

BALE SIZE & CONTENTS | |

|---|---|

Bale size (width x diameter)

| 85 cm x Ø 90 cm |

Bale volume | 0.55 m3 |

Weight | 75-150 kg |

Number of bales per hour | Max. 50-70 |

Pick-up | |

|---|---|

Working width | 1,70 mtr |

Number of tooth rows | 4 |

Feed rotor with cutting blades | Yes, incl. 7 cutting blades (mechanical operated) |

Dropfloor | Yes (hydraulically operated) |

MOUNTING & DRIVE SYSTEM | |

|---|---|

Attachment to tractor | a) Drawbar for lifting device, CAT. II |

b) Drawbar for lower / upper coupling

| |

PTO | 1-3/8″ (6 splines) – 540 RPM |

HYDRAULIC SYSTEM | |

|---|---|

Hydraulic System | Open center hydraulics from tractor

|

Hydraulic connections | 1 pressure connection 1/2″ 1 pressure return connection 3/4″ Minimum 25 ltr/min flow rate

|

Load-sensing hydraulic system | Optional |

ELECTRIC SYSTEM | |

|---|---|

Electrical connections | 12 volt DC & road lighting |

Operator system | CrossControl 7″ TFT touchscreen control (dust and water resistant) |

WINDING & BINDING SYSTEM | |

|---|---|

Wrapping System | Double wrapping arm with 500 mm film stretch units |

Binding System | Net binding / Film binding (optional) |

Film break detection system

| Yes, automatic for both binding & wrapping system

|

Extra storage of wrapping film (rolls) | 11 |

Additional storage net (rolls) | 1 |

Downloads

Download our digital brochure of the KNOLL MidiFix II here.

Looking for working drawings, manuals or parts lists?

Please feel free to contact us.

ADDITIONAL OPTIONS

KNOLL attaches great importance to meeting the expectations of customers worldwide. In order to meet all requirements and wishes, KNOLL MidiBalers can be equipped with additional options so that the machines perfectly match the working environment in which the performance is to be delivered.

APPLICATIONS

Processing various crops and materials into high-density round bales is what KNOLL MidiBalers excel at!

Our MidiBalers can be used to process grass, hay, straw and alfalfa, among others, into high-density round midi bales.

Grass

Hay / haylage

Straw

Examples of other materials that can be processed with a KNOLL MidiFix.

Alfalfa | Lucerne