Knoll Multibaler 1220

The KNOLL MultiBaler 1220 is a versatile MultiBaler, developed for the baling & wrapping of various (fibre-rich) materials.

The MultiBaler 1220 provides a high efficiency and is the suitable machine for any professional. This machine makes the packaging of silage and other products simple, easy and extremely efficient!

THE VERSATILE ALL-ROUNDER

The “MultiBaler 1220” is a machine that can be used in a wide range of applications, both stationary and mobile and for small and large jobs.

Because of the round bale format that is produced with the KNOLL MultiBaler 1220, this machine is suitable for various users and circumstances and for deployment on own farms or for commercial use

BASIC INFORMATION

- Bale size: 100 cm (width) x 100-120 cm (Ø)

- Bale volume: 0.80 - 1.10 m3

- Bale weight: 500-900 kg. (material dependent)

- Bunker volume: 4.00 m3

- Bale chamber system with 2 drive chains and 107 tight bars

- Double arm wrapper with 750 mm film stretchers

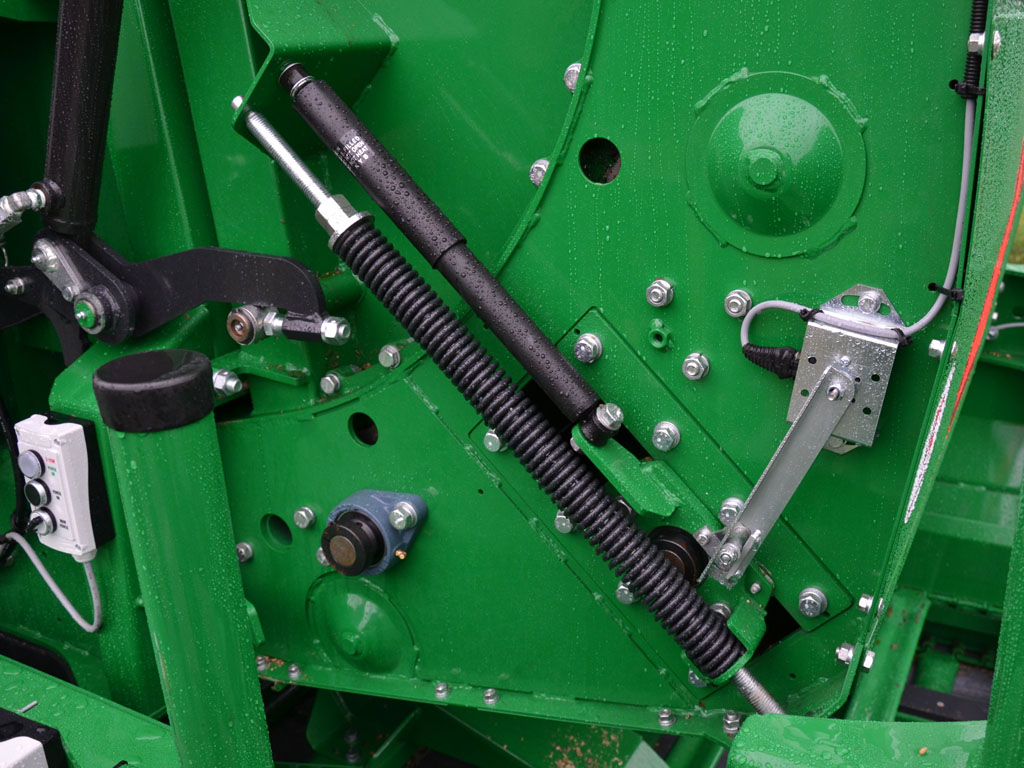

- Automatic film break detection system

- On-board hydraulic system with oil cooler

- Binding system for mantelfilm and/or net

- Integrated return system for recycling of crumb losses

- Modern computer for fully automatic operation

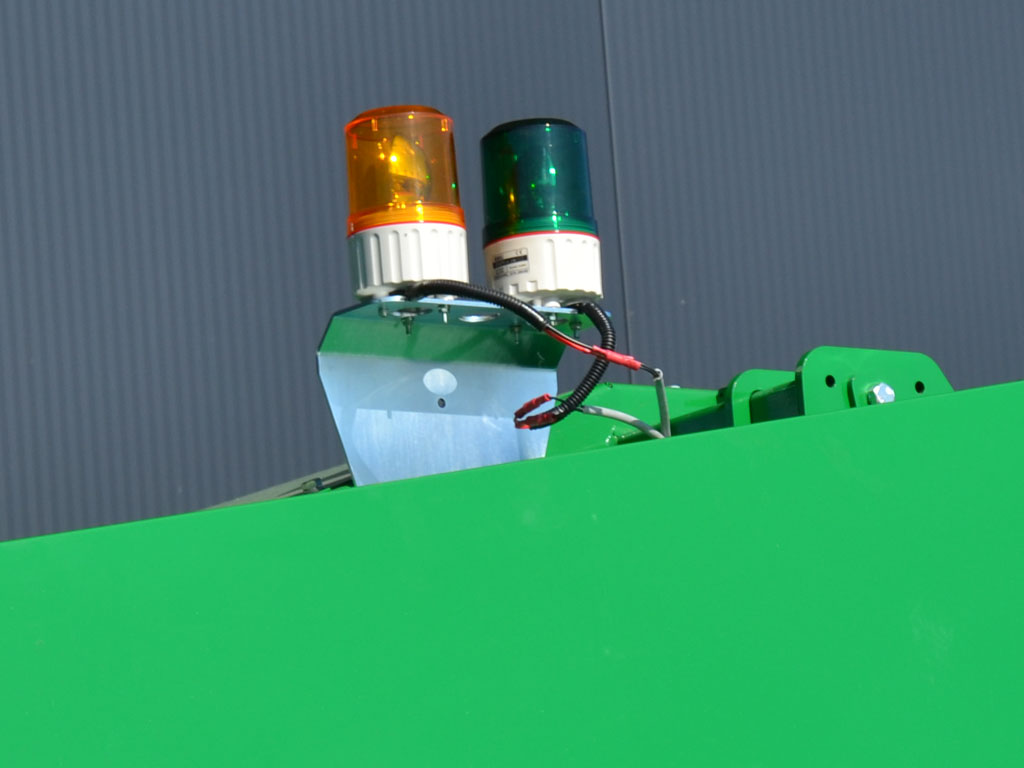

- Signal lamps for process display during automatic working mode

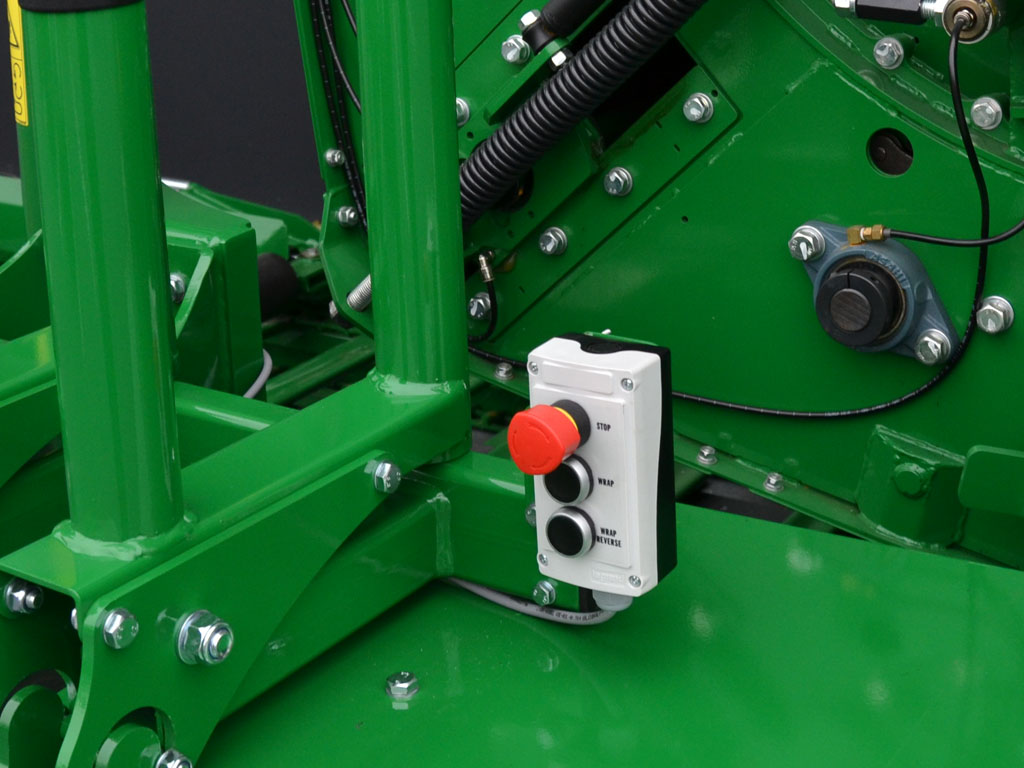

- External keypads on the machine for fast operation of function

- Tandem chassis with Flotation tyres 500/50 R17

- Additional storage for 12 reels of film

- Additional storage for 1 roll of mantelfilm / net (optional for 5 reels)

COST-EFFECTIVE WORKING WITH HIGH CAPACITY!

The MultiBalers from KNOLL are universally usable due to their robust construction. This multifunctionality makes the machines all-rounders for everyone.

KNOLL MultiBalers work worldwide to provide customers with the best products and performance!

The KNOLL MultiBaler 1220 is a machine that guarantees a high capacity and reliability (number of bales/hour).

Sophisticated technology and an efficient work process ensure the highest possible output.

Being an owner of a machine means paying attention to the Total Cost of Ownership. KNOLL machines are equipped with high quality parts and require little maintenance, which results in a long service life and a low cost per bale.

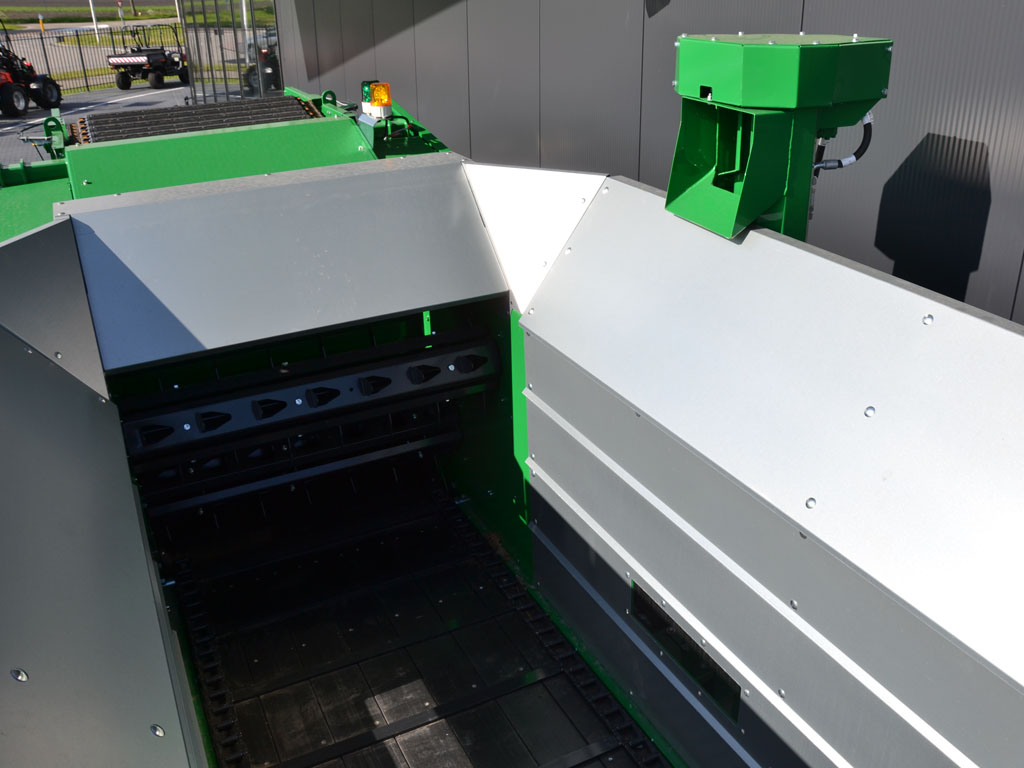

4.00 M3 INFEEDING BUNKER

The MultiBaler 1220 is equipped with a 4.00 m3 bunker. The bunker is fitted with a bottom chain with conveyors, making it easy to feed in many types of material.

Loading the bunker is possible in several ways. In stationary use with a tractor equipped with a front loader. In mobile use directly by the chipper.

APPLICABLE FOR MANY MATERIALS

The MultiBaler 1220 is equipped with a balechamber system that makes it possible to process various types of material.

The bale chamber consists of 2 drive chains in combination with 107 tight bars. This bale chamber in combination with the flow of material through the machine makes it possible to process various (short) materials into the best round bales!

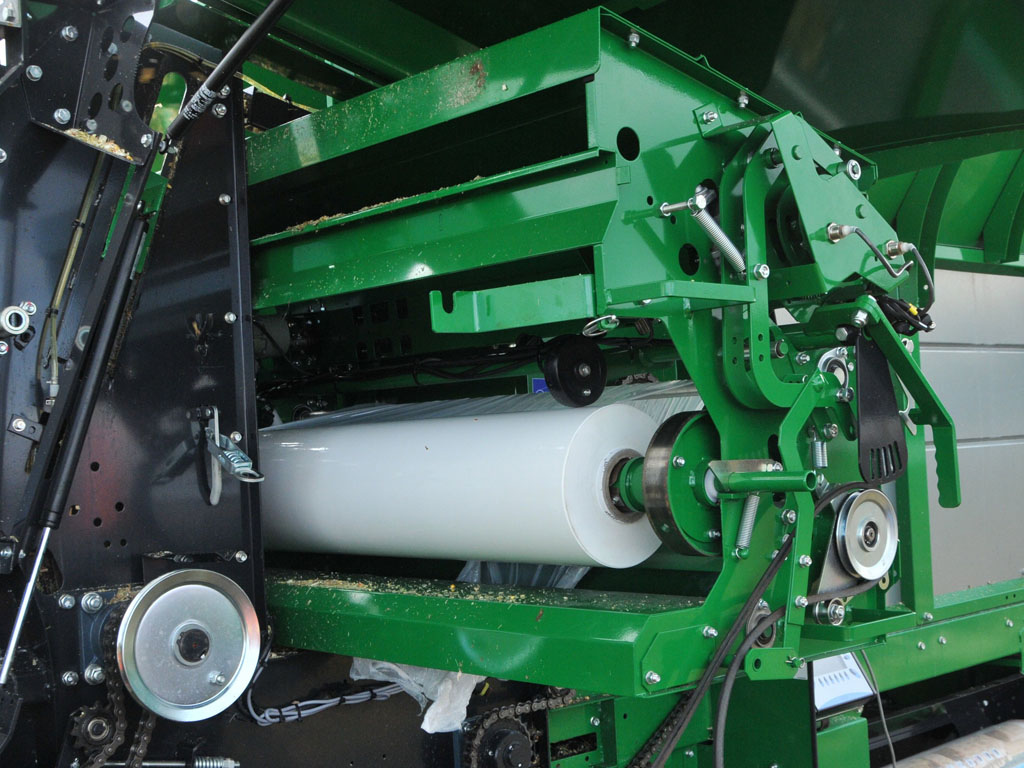

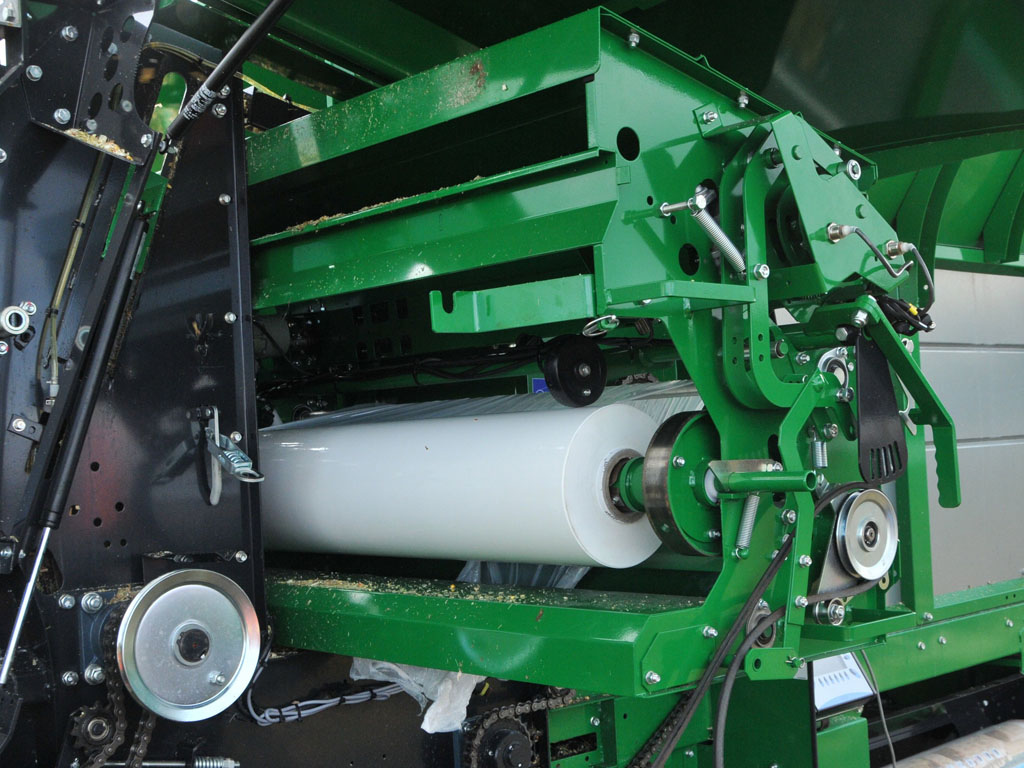

FILM- & NETBINDING SYSTEM

KNOLL MultiBalers are standard equipped with a binding system where both net and mantelfilm can be used. The choice of net or mantelfilm depends on the type of material or the user's requirements. In both cases the binding system of the MultiBaler 1220 ensures a neat finish of the pressed bale, before it is wrapped.

EFFICIENT WRAPPING

The final step is wrapping the bale with film. From the bale chamber the bale is moved to the wrapping position. This 'smart' movement of the bale through the combined return system of the machine and the wrapper gives the machine a high capacity. The automatic wrapping system is equipped with film breakage detection for efficient operation without unnecessary downtime.

MOBILE & STATIONARY USE

The KNOLL MultiBaler 1220 can be used in many ways to do what the machine is meant for, making high quality round bales in a very efficient way.

The machine can be used both stationary and mobile. This makes MultiBaler 1220 multifunctional and allows the machine to be used effectively by users

TRANSPORT & LOGISTICS

KNOLL MultiBalers impress with their flexibility. The composition of the machine ensures that it can be used in a very short time to get any job done. Both mobile and stationary. This is an important feature for the demanding user who visits different locations during a working day. The processing of materials into round bales ensures first-class quality and a versatile product through high compaction. Bales can be stored for a long time and moved easily, unlike a loose product.

Media

Watch videos and pictures of the KNOLL MultiBaler 1220 below.

HOW DOES THE MULTIBALER 1220 WORK?

1. Loading and feeding of material

Loose material should be loaded from above into the bunker of the machine. This can be done using a tractor unit + front loader, crane or wheel loader. The feed bunker can also be loaded from the ground or in combination with a silage wagon using the optional ''KNOLL Drop bunker''.

The bunker is equipped with movable side plates, which reduces the height for loading.

After loading, the material is transported to the bale chamber fully automatically by means of a bottom chain

The bottom chain automatically pauses when too much material is fed in and thus adjusts itself to the type of material.

Shortly before the bale chamber, two dosing rollers ensure a regular distribution and flow of material towards the bale chamber.

2. Compacting into round bales

The material is compacted in the bale chamber resulting in a volume reduction of up to 50-70%. This depends on the type of crop or material and the dry matter content.

The bale chamber of the MultiBaler 1220 is fitted with two heavy-duty drive chains with 107 tight bars between them. This system together ensures a closed bale chamber.

Each tight bar exerts pressure and traction on the material during baling, ensuring shape-retaining bales.

This special chain system handles many short-cut materials and shapes them into a perfectly shaped bale.

The "horizontal flow" of material through this machine also makes it possible to sometimes to handle little bit longer material as well.

3. Bale wrapping/ net wrapping

After compacting the material into a round bale, it is important that the bale is tied properly with net or mantelfilm before it leaves the bale chamber.

Secure film or net binding ensures perfectly shaped bales. The MultiBaler 1220 owner can choose whether to use net or sheeting for this process.

Changing between net or film is simply a matter of changing a setting in the machine's computer and installing the correct roll.

The ''film & film'' principle is based on a number of layers of mantelfilm in combination with wrapping film that is tied around the bale and guarantees a high press density and good bale shape. This principle also provides a better oxygen barrier, resulting in a better end product with a higher yield.

4. Integrated returnsystem.

KNOLL MultiBalers are equipped with an integrated return system for recycling "crumb losses".

During the processing of (short) materials, small losses always occur. With the help of the return system, no product is lost.

The return system consists of a construction that is located under the entire length of the press chamber and wrapper. From here, the losses are transported to the front of the machine by means of a bottom chain. The vertical return auger is located at the front. This upright system is equipped with two augers that move the material upwards and "recycle" it back into the infeed bunker.

Material losses are reduced to a minimum by the presence of a return system.

5. Automatic wrapping with film control

KNOLL MultiBalers are equipped with an ingenious wrapping system. When the bale is ready in the bale chamber, it is automatically transferred to the wrapper. With the MultiBaler 1220, both the return system and the wrapping system are combined, ensuring an easy and efficient movement of the bale. This also ensures a very clean transfer and at the same time effective handling of the crumb losses.

The wrapper is equipped with a wrapping arm with two film stretchers for 750 mm film rolls and two cut-and-hold cutting systems for the wrapping film.

During the bale wrapping the process is monitored by the film control system. When a film roll is empty or when it breaks, the system reacts automatically.

Features

See all features of our KNOLL MultiBaler 1220.

Reliable operating system

Variable size bales

Indicative signal lights

Film & netwrap system

"On-board" hydraulic system

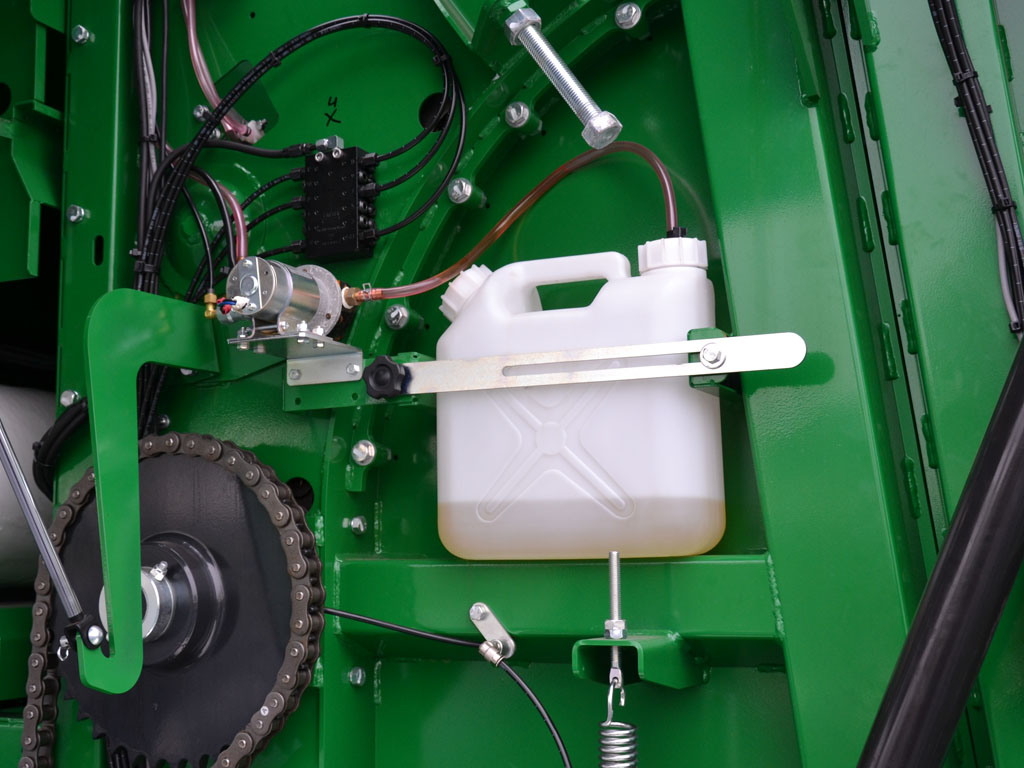

Automatic oil lubrication system

External control of wrapper

TECHNICAL DATA

DIMENSIONS & WEIGHT | |

|---|---|

Transport length

| 8,90 mtr |

Transport width

| 2,87 mtr |

Transport height

| 3,10 mtr |

Volume infeeding bunker

| 4.00 m3 |

Wheels

| 500/50-17 |

Weight

| 6.800 kg |

REQUIRED POWER | |

|---|---|

Required tractor power

| Min. 70kW / 95hp |

BALESIZE & VOLUME | |

|---|---|

Bale size (width x diameter)

| 100 cm x Ø 100-120 cm |

Bale volume

| 0.80 – 1.10 m3 |

Bale weight | 450-800 kg |

Number of bales per hour

| 40-45 |

MOUNTING & DRIVE SYSTEM | |

|---|---|

Mounting to a tractor

| Swivel flange eyelet / K80

|

PTO | 1-3/8” (6 splines) – 540 RPM

|

HYDRAULIC SYSTEM | |

|---|---|

Hydraulic System

| “On-board” hydraulic system with oil cooler

|

Hydraulic connections

| No connections neccessary

|

ELEKTRIC SYSTEM | |

|---|---|

Elektric connections

| 12 volt c connections

|

Operator system | Electronic control unit ( dust- and water resistant)

|

WRAPPING & BINDING SYSTEM | |

|---|---|

Wrapping system

| Double wrap arm with 750 mm film stretch units

|

Binding system

| Filmbinding en Netbinding

|

Filmbreak detection system

| Yes, automatic for both tie & wrap system

|

Extra storage of wrapping film (reels)

| 12 |

Extra storage for mantelfilm/net (reels)

| 1 |

Downloads

Download here our digital brochure of the KNOLL MultiBaler 1220.

Looking for working drawings, manuals or spare parts lists?

Please feel free to contact us.

ADDITIONAL OPTIONS

KNOLL is committed to meeting the expectations of customers worldwide. In order to meet all requirements and wishes, KNOLL Multibalers can be equipped with additional options so that the machines perfectly match the working environment in which they are to be used.

APPLICATIONS

The processing of chopped or shredded crops and materials into round bales with a high density is what the KNOLL MultiBalers excel at!

Our customers use our MultiBalers to bale a wide range of different materials.

Corn

Chopped grass

GPS (Whole Plant Silage)

TMR (Total Mixed Ratio)

CCM (Maize Cob Scrap)

RDF / Waste

Examples of other materials that can be processed with a KNOLL MultiBaler 1220

Alfalfa | Lucerne | Dried manure | Cereals | Wood chips | Sugar beet pulp | Peat | Hemp | Cotton | Plastic