Knoll Multibaler XL

The KNOLL MultiBaler XL is the flagship of the MultiBaler series. This machine was developed for professionals with high demands

With its multifunctional use, its robust construction and its unrivalled capacity, this model distinguishes itself as the best all-rounder of its kind.

THE GAME CHANGER IN THE MARKET SEGMENT

We have noticed that the demand for processing chopped and/or shredded products into round bales is increasing. With this in mind, we have developed a completely new concept that is unique in its properties and capabilities. The KNOLL MultiBaler XL can rightly be called a game-changer.

The first machine that makes it possible, in combination with a self-propelled harvester, to process various crops such as maize and grass directly in the field into chopped round bales.

The KNOLL MultiBaler XL gives more possibilities, and in our eyes, that is what we can use to help you move forward, our motivation to keep developing!

BASIC INFORMATION

- Bale size: 100-115 cm. (Ø) x 120 cm. (width)

- Bale volume: 0,95 - 1,25 m3

- Bale weight: 500-1350 kg (material dependent)

- Bale volume: 8.00 m3

- Press chamber equipped with 17 chamber rollers and durable slide bearings

- Patented Power-Grip-4 bale chamber belts (2 pieces)

- Hydraulic pressure control system for bale density

- Double arm wrapper with 750 mm film stretchers

- Automatic film break detection system

- Automatic single roll wrapping speed adjustment

- Patented tying system for mantelfilm or net

- Integrated return system for recycling crumb losses

- Special feed rotor for optimal control of the crop flow

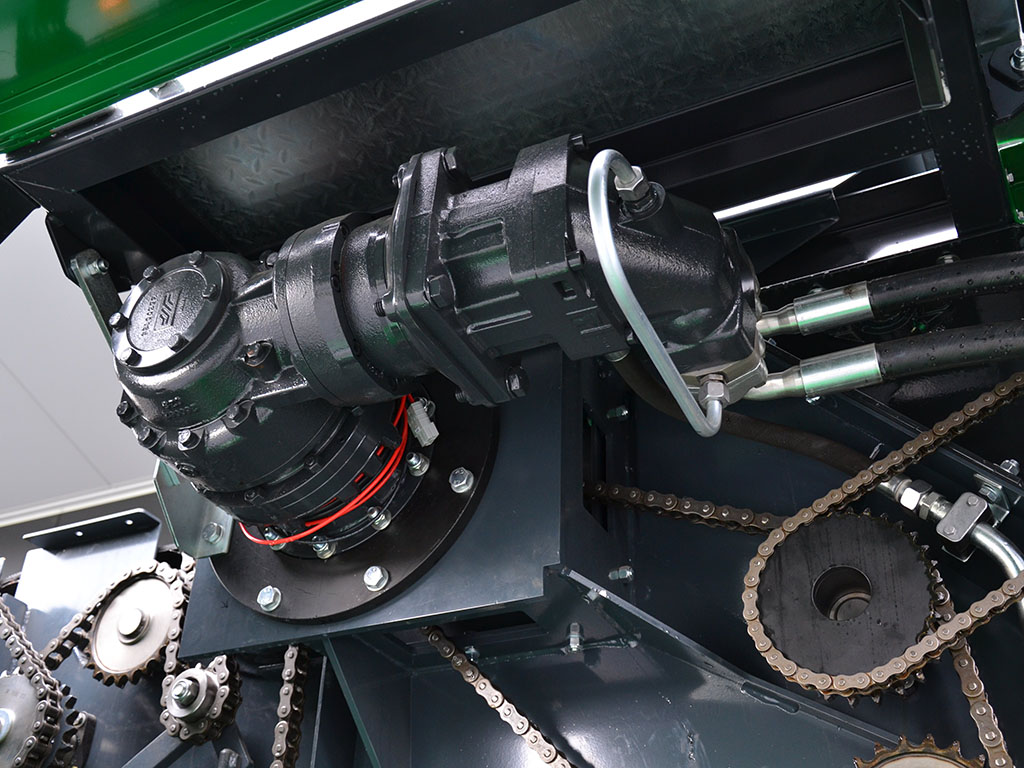

- On-board hydraulics (load-sense) - Danfoss

- Proportionally hydraulically adjustable functions

- Air-cooled oil cooler with reversing fan

- Tandem chassis with Flotation tyres, size 560/60 R22.5

- Air brake system for up to 50 km/h

- IQAN 10'' TFT touch screen control console with visual process display

- External keypads on the machine for quick control of functions

- Rimote® system for wireless connection of the machine for service and operation

- Integrated camera system with two cameras

- Integrated LED light system with 4 working lights

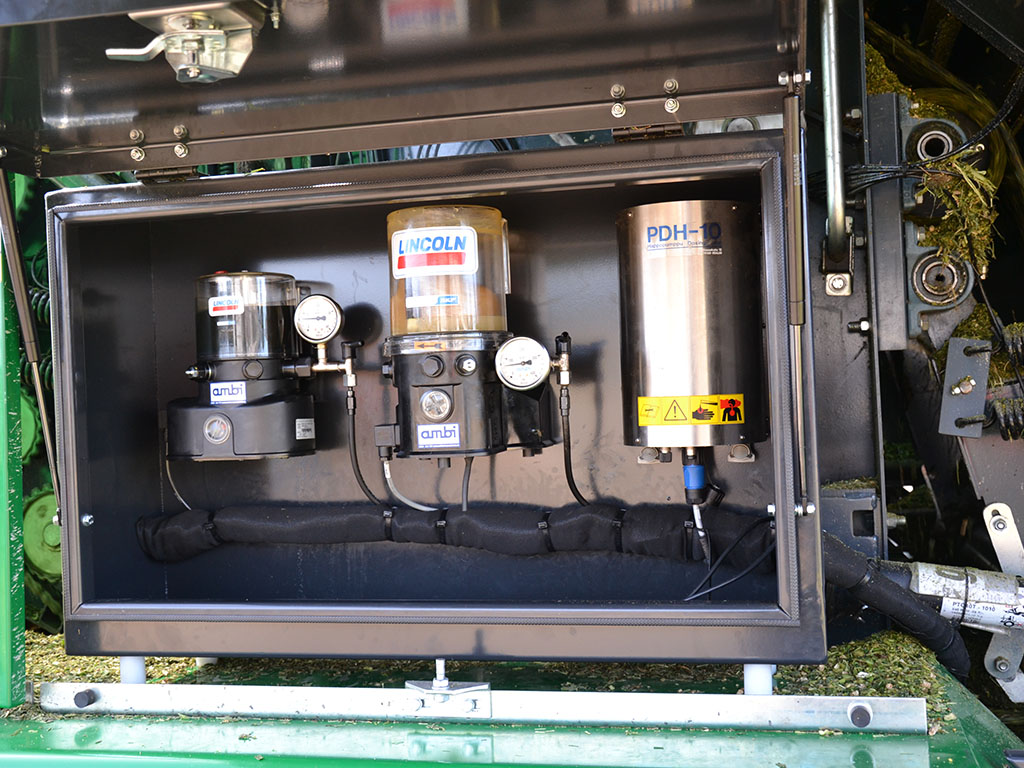

- Automatic central lubrication system for oil and grease for drive chains and bearings

- Additional storage for 12 rolls of binding film

- Additional storage for 6 rolls of wrapping film / net

UNIQUE AND VERSATILE, THE MOST EFFICIENT OF ITS KIND!

The KNOLL MultiBaler XL is unique. The only machine that can work both stationary and mobile. Due to the design of the machine it is not necessary to change the working mode of the machine. Very easy and you can get straight to work. This feature provides versatility and more possibilities to use the machine effectively, with ultimately a better result….. and satisfied users!

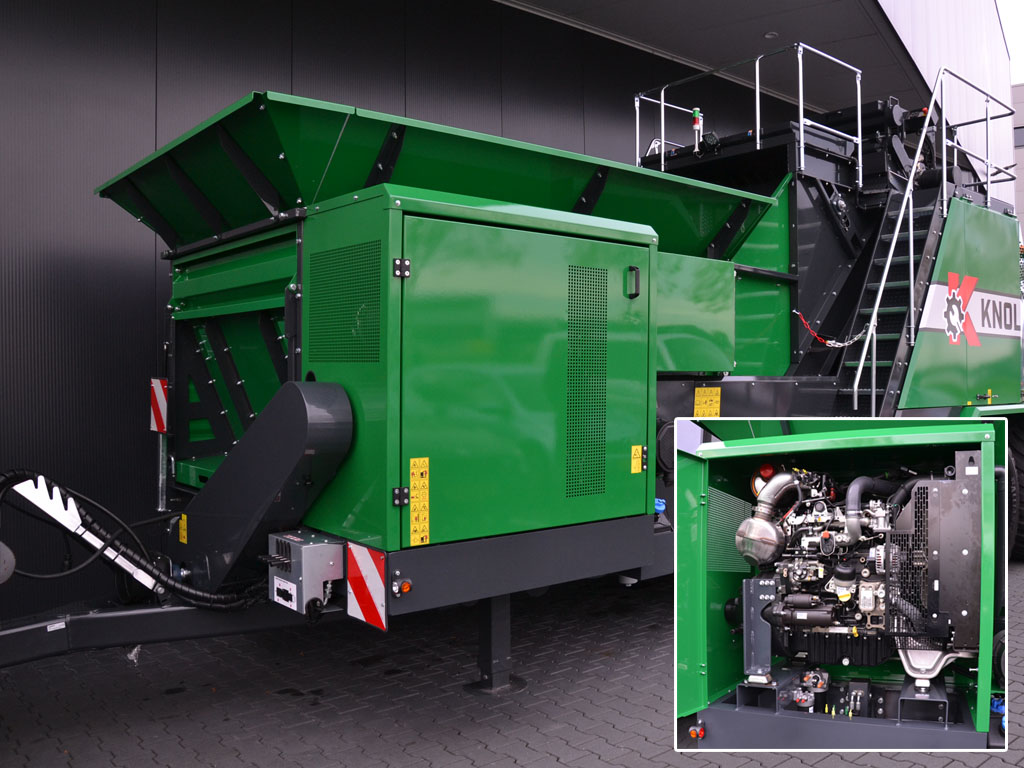

8.00 M3 - LARGE INFEEDING BUNKER

The machine's feed bunker has a volume of 8.00 m3. The bunker is designed so that it can be loaded with any type of machine.

For example a tractor with a front loader, shovel, crane or any other loading solution.

The bunker is equipped with side panels that can be folded down to facilitate loading.

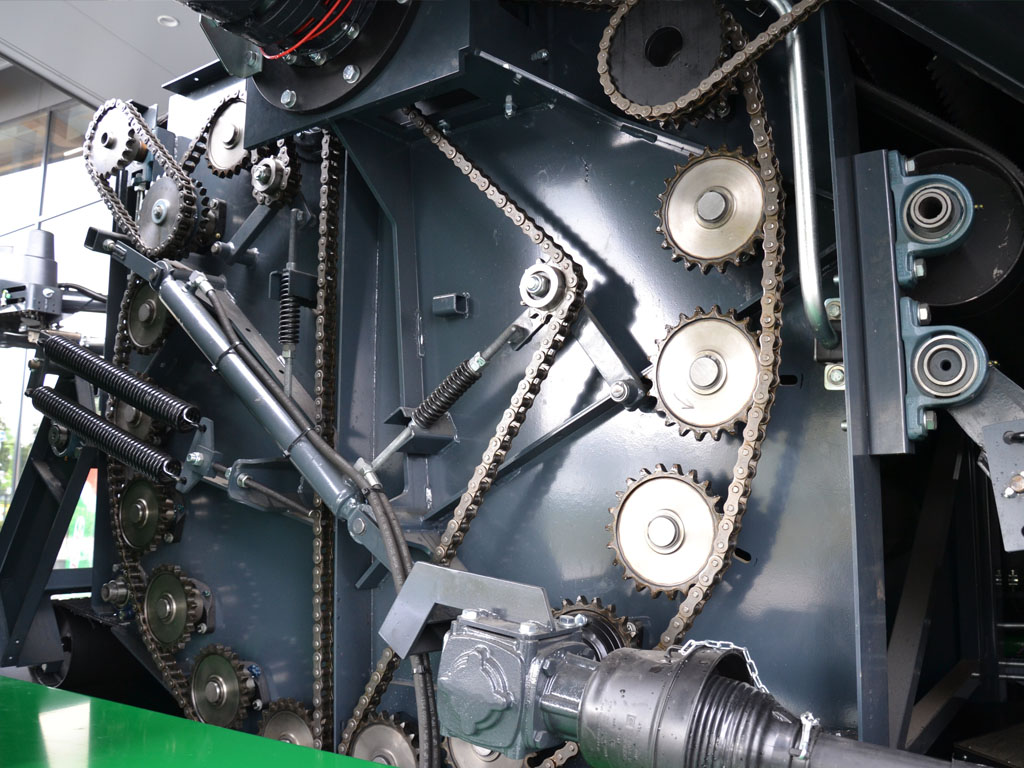

DURABLE BALE CHAMBER SYSTEM

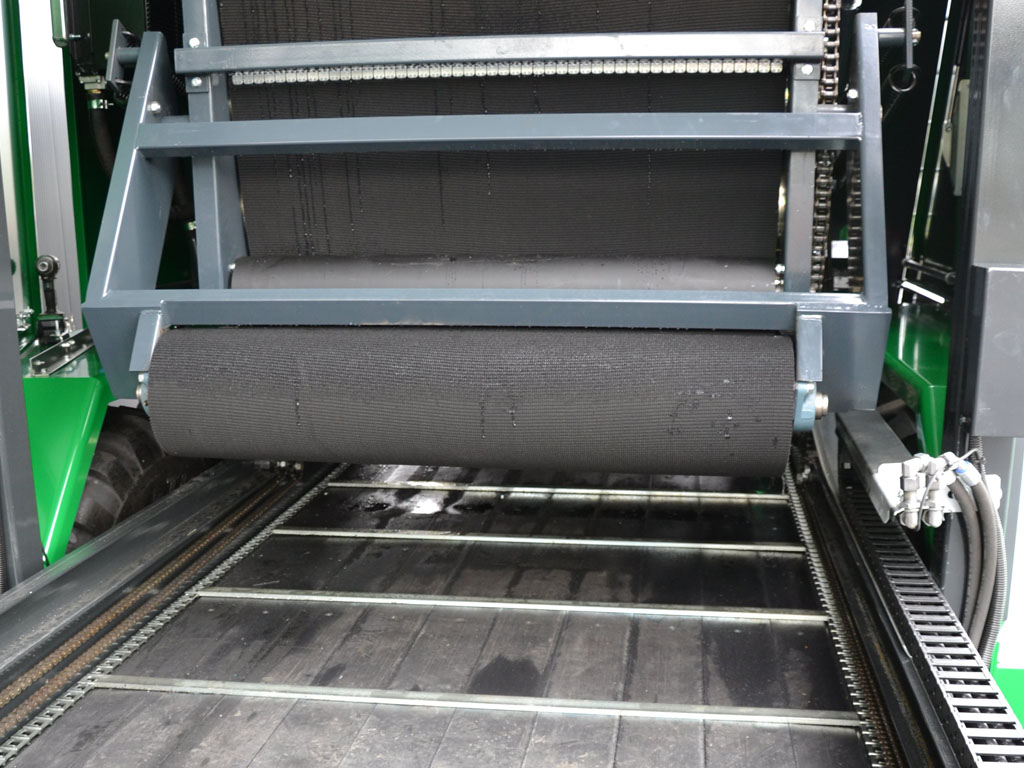

The heart of the MultiBaler XL consists of a bale chamber that is fitted with 17 bale chamber rollers in combination with 2 bale chamber belts.

This combination enables a wide variety of short materials to be processed to the best possible

compacted round bales! The wear-resistant steel of the bale chamber enables long-term operation without maintenance.

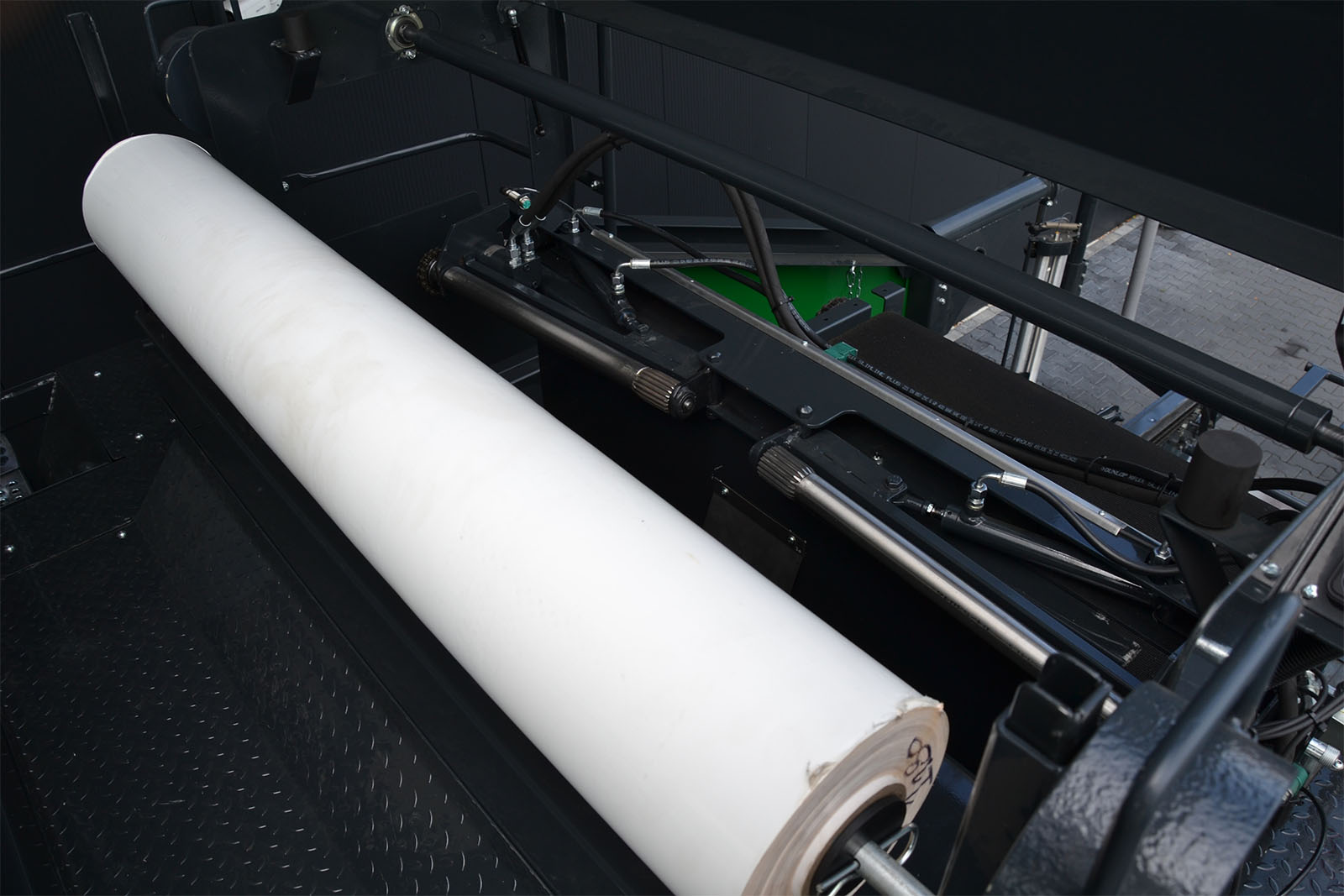

FILM & NET WRAPPING SYSTEM

The strength of a good and effective operation usually lies in its simplicity. We have succeeded in equipping the KNOLL MultiBaler XL with a very simple working tying system. This system can be used for both mantel and net and ensures a neat finish of the pressed bale at all times, before it is wrapped.

CLEVERLY COMPLICATED

The wrapping system consists of the wrapping table and the wrapping arm. The wrapping table moves through a rail system from the loading position to the wrapping position. This rapid movement, in combination with the fast wrapping arm, gives the machine a high capacity. The ingenious wrapping system is equipped with many handy extras for good and reliable operation.

LOADING WITH ANY KIND OF LOADING EQUIPMENT

The spacious feed bunker can be loaded in a versatile way using various machines. For example, a tractor with a front loader, shovel, crane or any other loading solution. In addition, the feed bunker is equipped with side panels (both left and right) that can be folded down to reduce the height and facilitate loading, even with smaller machines.

UNIQUE COMBINATION, VERSATILE MOBILITY!

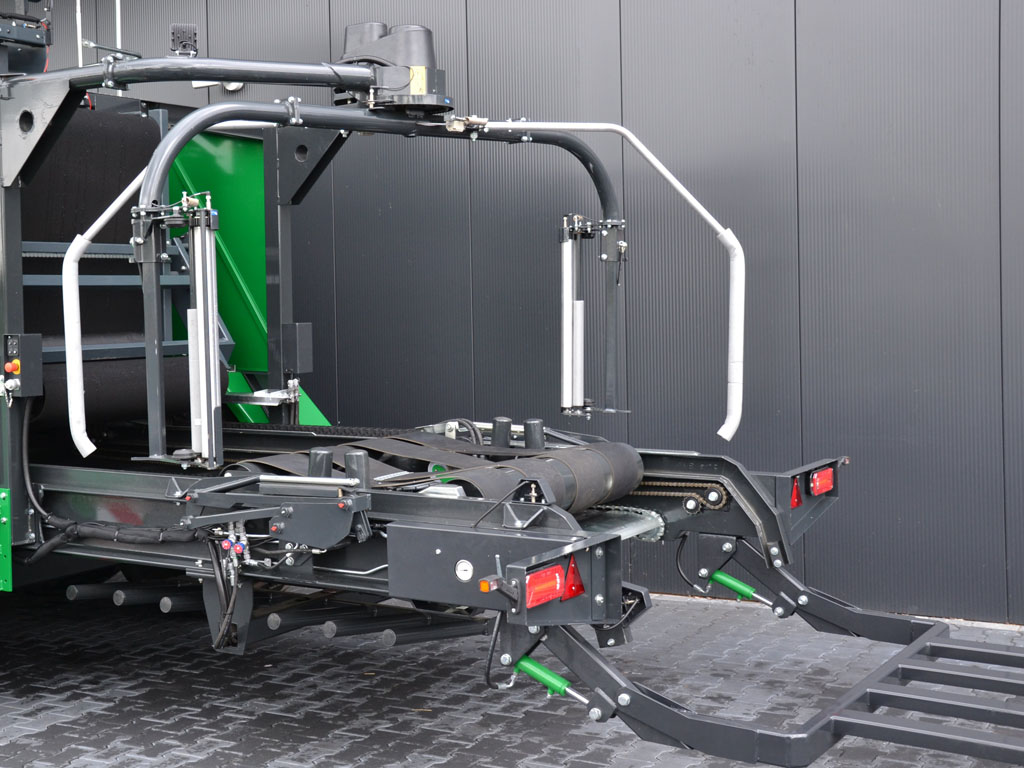

The KNOLL MultiBaler XL can also be used mobile in a very efficient way. The combination in the field can be used with:

1. Directly in combination with self propelled chopper (PTO driven)

2. Driving next to the chopper, driven and pulled by a tractor

3. In combination with a tractor fitted with a front-mounted forage harvester

STATIONAIRE USE

The KNOLL MultiBaler XL distinguishes itself by being both stationary and mobile. These options make the machine multi-purpose.

During stationary use, the machine’s feed bunker is filled. In fully automatic mode, the control system ensures a regular feeding process. The speed of the bunker bottom chain and the feed chain are automatically monitored and controlled by the control system of the MultiBaler XL.

MOBILE USE

The KNOLL MultiBaler XL distinguishes itself from all other machines on the market by offering the possibility to use the machine very efficiently and effectively directly in the field. It is even possible to use the machine in one pass with a selfpropelled harvester (equipped with PTO).

This simplifies the use and often saves 1 to 2 additional operations that are necessary for stationary use. The crop is processed into a bale immediately after chopping, guaranteeing the best end product.

KNOLL DROPBUNKER FOR LOADING BALER DIRECT FROM SILAGE WAGON

When loading material directly from a silage wagon, the ''KNOLL Dropbunker'' offers the solution. This makes the use of the MultiBaler XL even more versatile. The drop bunker can of course also be used in a fixed stationary position! This drop bunker with a capacity of 3.50m3 is hydraulically driven and the feed speed can be perfectly adjusted for each type of material by means of a speed control valve. In this way, material from the field can be stationary processed into round bales in a short time.

PROCESSING DIFFERENT TYPES OF GRASS DIRECTLY IN THE FIELD

The KNOLL MultiBaler XL answers a frequently asked question. Is it possible to process chopped grass into bales? YES!

The KNOLL MultiBaler XL is the first machine to make it possible to process chopped round bales directly on the field.

The MultiBaler XL was developed from the idea that it should be possible to process different chopped/shredded materials into bales. A variety of grass types can be baled, e.g. grass, alfalfa, fibre hemp, grain, GPS, etc.

Media

See below for videos and pictures of the KNOLL MultiBaler XL.

HOW DOES THE MULTIBALER XL WORK?

1. Loading and feeding the material

The (chopped ) material can be loaded from above into the feed bunker. This can be done either by driving the harvester or by using a crane or shovel. The feed bunker of the KNOLL MultiBaler XL has a volume of 8.00m3. In automatic working mode, the material is moved from the bunker to the inclined feeder conveyor. From here the press chamber is filled from the top.

Automatic speed control of the bottom chain in combination with the feed conveyor always ensures most optimal material feeding. In addition, the KNOLL MultiBaler XL is equipped with a small dosing roller in the feed bunker to ensure a good distribution of the material on the sloping feed conveyor.

The feed belt ensures efficient filling of the bale chamber from above. The bunker is also equipped with a special large dosing roller to regulate the crop flow, e.g. for long materials.

2. Forming and compacting into round bales

The MultiBaler XL is equipped with an adjustable hydraulic press pressure system. This allows the desired baling pressure to be set for each type of material, for bales of the best quality and shape. The bale chamber is basically equipped with 17 bale chamber rolls in combination with two ''Power-Grip 4'' bale chamber belts. This combination of rolls & belts makes it possible to process many types of material with minimum losses.

3. Bindingthe bale with net/mantelfilm

The feeding, binding and cutting of the net/foil is performed step by step in the automatic working mode.

In addition, this system is equipped with external ''keypads'' that make it easy to operate and (re)start the binding system when a new roll is installed.

4. Recycling of small material losses

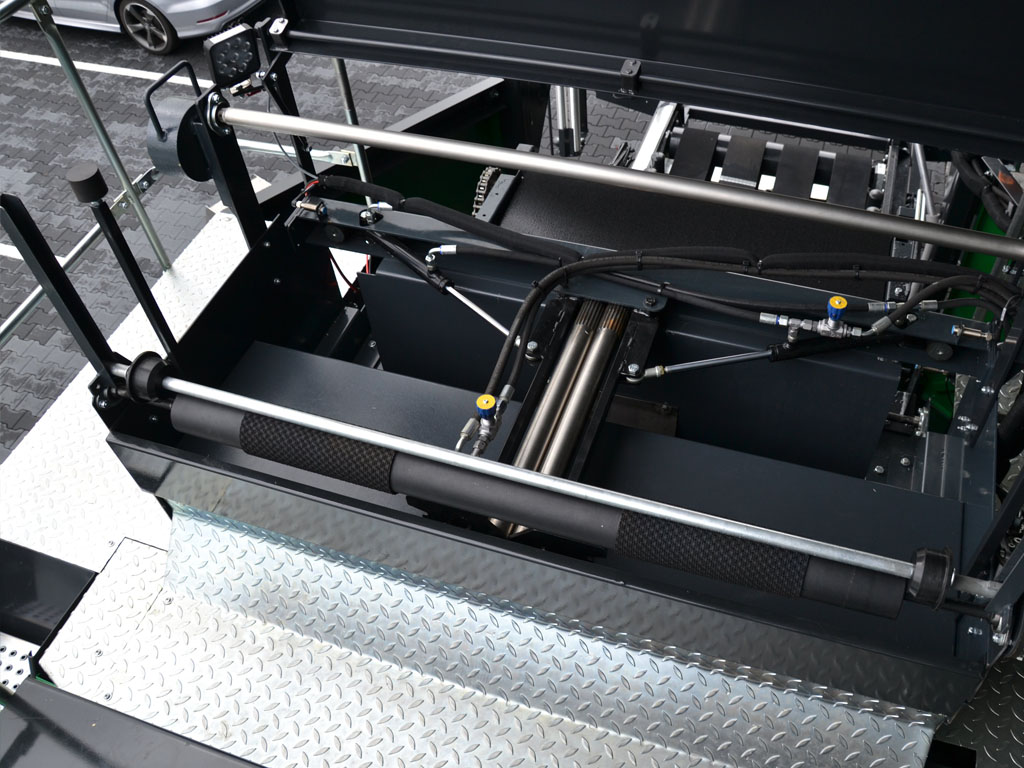

5. Wrapping with automatic film control

The wrapping table moves forwards and backwards through a guide rail. From the bale chamber the bale is rapidly transported from the loading position to the wrapping position. This transport system of the wrapping table also works well in hilly areas when the machine is mobile.

The wrapper is equipped with a wrapping arm with two 750 mm film-stretch units. Here the bales are quickly and carefully provided with the correct number of layers of wrapping film after pressing for good sealing and preservation of the bale.

For optimum control, the wrapper is equipped with automatic film breakage detection. As soon as a film roll is empty or the film tears, the wrapping machine stops or continues wrapping with one reel and the speed is automatically reduced to ensure that the film overlap always remains 50%.

The carefully developed film cutters always ensure accurate cutting and retention of the film.

Features

Watch all features ofthe KNOLL Multibaler XL

Reliable operating system for the best performance

Hydraulic drive system for the bale chamber

External "keypads" for important functions

IQAN 10'' TFT control system

Through Rimote® the machine is always "connected" and globally accessible for data exchange.

Automatic oil & grease lubrication system

This system consists of two automatically controlled pumps that deliver a measured quantity of oil and grease necessary for the use of the machine in all conditions for sustainable operation and optimum maintenance.

TECHNICAL DATA

DIMENSIONS AND WEIGHT | |

|---|---|

Transport length | 11,37 mtr |

Transport width | 2,97 mtr |

Transport height | 3,86 mtr |

Feed hopper volume | 8.00 m3 |

Wheels | 560/60 R22.5 |

Weight | 10.640 kg |

Braking system | Air brake system (double line) for max. 40 km/h |

REQUIRED POWER | |

|---|---|

Required tractor power | Min. 135hp / 100kW |

BALE SIZE & CAPACITY | |

|---|---|

Bale size (width x diameter) | 120 cm x Ø 100-115 cm |

Bale volume | 1.25 m3 |

Bale weight | 500-1350 kg |

Number of bales per hour | 50-60 |

ATTACHMENT & DRIVE SYSTEM | |

|---|---|

Attachment to tractor | Rotatable flange eye / K80 |

PTO | 1-3/8″ (6 splines) – 1000 RPM |

HYDRAULIC SYSTEM | |

|---|---|

Hydraulic system | Danfoss on-board load sensing hydraulic system with oil cooler |

Hydraulic connections | No connections required |

ELECTRIC SYSTEM | |

|---|---|

Electrical connections | 12 volt DC & road lighting |

Operator system | IQAN 10″ TFT touch screen (dust and water resistant) |

WRAPPING & BINDING SYSTEM | |

|---|---|

Wrapping system | Double wrap arm with 750 mm film stretch units |

Binding system | Filmbinding and net binding |

Film break detection system | Yes, automatic for both binding & wrapping system |

Extra storage of wrapping film (rolls) | 12 |

Extra storage mantle film / net (rolls)

| 5 |

Downloads

Download here our digital brochure of the KNOLL MultiBaler XL.

Looking for working drawings, manuals or spare parts lists?

EXTRA OPTIONS

KNOLL is committed to meet the expectations of customers worldwide. In order to meet all requirements and wishes, KNOLL Multibalers can be equipped with additional options so that the machines perfectly match the working environment in which the performance has to be delivered.

Click on an image for more information.

APPLICATIONS

The processing of chopped or shredded crops and materials into round bales with a high density is what the KNOLL MultiBalers excel in!

Our customers use our MultiBalers to bale a wide range of different materials.

Corn

Chopped grass

GPS (Whole Plant Silage)

TMR (Total Mixed Ratio)

CCM (Maize Cob Scrap)

RDF / Waste

Examples of other materials that can be processed with a KNOLL MultiBaler XL.

Alfalfa | Lucerne | Dried manure | Cereals | Wood chips | Sugar beet pulp | Peat | Hemp | Cotton | Plastic